Popular in your industry

Top categories

About crimping tool

The Essentials of Professional Crimping Tools for Precision Tasks

In industries where precise wire and connector unions are critical, a professional crimping tool tailored for precision tasks is indispensable. These instruments are meticulously crafted to deliver the exact force necessary for a secure bond, often incorporating a ratchet system to maintain consistent pressure—a key factor for connections that adhere to industry norms.

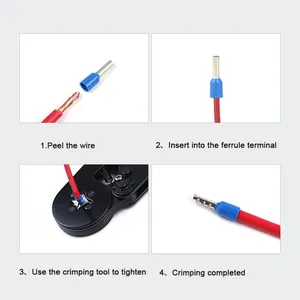

Professionals in electronics, telecommunications, and manufacturing rely on these tools for their fundamental ability to forge precise and dependable connections. The use of a crimping tool is quite intuitive: one positions a terminal within the tool's jaw, inserts the wire, and then compresses the handles, which fastens the terminal to the wire, ensuring an electrically conductive and mechanically sound joint.

To operate effectively, a crimping tool must apply adequate force to slightly deform the terminal and wire, fostering close contact between conductors and establishing a path of low resistance for electrical currents. This is accomplished with finely machined metal dies that compress the terminal and wire to create the crimp.

Varieties of Professional Crimping Tools for Precision Work

The market presents an array of professional crimping tools, each suited to specific tasks and user preferences:

-

Hose Crimping Machines: These robust machines are built to secure fittings to hoses by crimping a metal collar around them, a common necessity in hydraulic systems where high-pressure hoses are essential.

-

Terminal Crimping Tools: Tailored for affixing electrical terminals to wires, these tools are indispensable for quick, reliable connections in automotive and electrical applications.

-

Hydraulic Crimping Tools: Suited for heavy-duty tasks, hydraulic crimping tools accommodate larger wires and thicker materials, leveraging hydraulic force to ensure a steadfast crimp.

-

Battery Powered Crimping Tools: These tools offer convenience and mobility, favored by technicians for on-site repairs or installations.

-

Manual Crimping Tools: Ideal for lighter tasks or hobbyist projects, these compact tools are easy to handle and work with finer gauge wires.

Each tool variant is tailored to meet the demands of specific industries, taking into account the materials involved and the force required for an appropriate crimp.

Selecting a Professional Crimping Tool for Precision Work

Choosing the correct professional crimping tool involves a thoughtful analysis of various aspects:

-

Application Requirements: The intended use will determine the appropriate tool. For instance, a ratcheting hand tool may suffice for crimping small connectors in electronics, whereas industrial settings might necessitate a hydraulic crimping machine.

-

Frequency of Use: The tool's usage frequency should guide your choice. Occasional tasks may call for a manual tool, while electric crimping machines can boost productivity in high-volume environments like factories or construction sites.

-

Handle Material: For prolonged use, the handle material should provide comfort. Ergonomic options such as plastic or soft grip plastic can alleviate strain from repetitive actions.

-

Jaw Surface: The connector type may necessitate either smooth or serrated jaws for optimal crimping efficacy.

-

Material Compatibility: Verify that the tool aligns with the materials you'll frequently handle. Some tools are specifically designed for high carbon steel crimp terminals, while others are more versatile.

-

Durability and Quality: Opt for tools constructed from sturdy materials like carbon steel, stainless steel, or hardened alloys for durability and sustained performance.

Professional Crimping Tools for Precision Work on Alibaba.com

Alibaba.com excels as a marketplace for sourcing professional-grade crimping tools, offering a comprehensive selection from global suppliers. Whether your business operates in electronics, construction, or any field demanding precision and reliable tools, Alibaba.com's network ensures you find the right equipment.

The platform's dedication to enabling global trade is reflected in its intuitive interface, which allows buyers to interact with suppliers in their own language and manage transactions efficiently on mobile devices. Alibaba.com also provides safeguards like Trade Assurance, ensuring secure and trustworthy exchanges by protecting payments until delivery confirmation.

Opting for Alibaba.com to fulfill your professional crimping tool needs means tapping into a system optimized for international trade. Alibaba.com emphasizes quality and supplier dependability, empowering small and medium-sized enterprises to engage confidently in the global marketplace with tools that meet their exacting standards for precision and efficiency.

Frequently Asked Questions on Professional Crimping Tools for Precision Work

What is the function of a professional crimping tool?

A professional crimping tool is instrumental in forming a robust connection between materials, typically wires, through compression. It is vital in sectors that demand secure, high-volume crimping like telecommunications, electronics, and construction.

What considerations are important when choosing a professional crimping tool?

In selecting a professional crimping tool, evaluate the materials you'll be working with, usage frequency, the tool's industry standard compatibility, construction material, and handle material for ergonomic comfort and longevity.

How can I ascertain if a professional crimping tool meets my industry's standards?

Verify the tool's specifications for compliance with your industry's standards. Tools designed for specific sectors like telecommunications will require precision, while others may be tailored for automotive or construction tasks.

Is a professional crimping tool universal for all wire types?

Professional crimping tools are not universally suitable for all wire types. It's crucial to use a tool that matches the wire gauge and material to prevent damage.

Can I obtain a professional crimping tool customized for my business needs?

Yes, many suppliers offer customization services such as OEM, ODM, and OBM to craft a crimping tool that aligns with your business's specific requirements.

Why is the handle material significant in a professional crimping tool?

The handle material is a key factor for ergonomic comfort and tool durability. Options like soft grip plastic or aluminum alloy can minimize hand fatigue during extended use.

What are the essential components to look for in a high-quality professional crimping tool?

For machinery repair or manufacturing tools, essential components to consider include the pump, motor, engine, gearbox, and pressure vessel to guarantee longevity and dependable operation.

How does the jaw surface impact the performance of a professional crimping tool?

The jaw surface is critical to a crimping tool's performance. Smooth jaws are typically recommended for delicate tasks to avoid damage, while serrated jaws may be needed for tougher materials that require a firmer grip.

When would I need a hydraulic crimping tool?

Hydraulic crimping tools are necessary for demanding tasks that call for substantial force, such as in construction or industrial manufacturing, providing enhanced power for more challenging crimping requirements.

What does after-sales service for a professional crimping tool entail?

After-sales services can encompass video technical support, online assistance, and field maintenance and repair services, varying by supplier and should be confirmed prior to purchase.

Are there specialized professional crimping tools for certain industries?

Certainly, there are professional crimping tools specifically engineered for industries like automotive repair, heavy machinery maintenance, telecommunications, and others, catering to the unique demands of each sector's applications.