Introduction to Ultrasonic Welding Machines

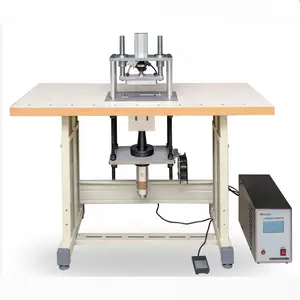

Ultrasonic welding technology has revolutionized the way we join materials, particularly plastics. At the heart of this innovation is the 2600w ultrasonic welding machine, a specialized device designed to meet the demands of various industries. This machine operates on the principle of high-frequency ultrasonic acoustic vibrations to weld materials, creating strong bonds without the need for adhesives or connective bolts.

Understanding the Mechanics of Ultrasonic Welding

The ultrasonic plastic welding machine is engineered to deliver precision and efficiency. It uses rapid, high-frequency vibrations to generate localized heat through surface friction, causing the plastic materials to melt and fuse upon cooling. This process is not only efficient but also environmentally friendly, as it eliminates the need for solvents or adhesives.

Applications and Versatility

The versatility of the ultrasonic welding equipment extends across various sectors, including automotive, packaging, and medical device manufacturing. Its ability to join complex components swiftly makes it indispensable for producing high-volume, repeatable assemblies. The plastic welding machine is particularly adept at joining dissimilar materials, which is often required in the production of consumer electronics and automotive components.

Features and Materials

A 2600w ultrasonic plastic welder is typically constructed from durable materials like aluminum and steel, ensuring longevity and resilience in industrial environments. The design of these machines allows for precise control over welding variables, which is crucial for achieving consistent weld quality. Furthermore, the adaptability of the ultrasonic welder to different materials highlights its role as a multifaceted tool in manufacturing.

Advantages of Ultrasonic Welding Machines

The high-power ultrasonic welding machine offers numerous advantages, such as rapid welding times, energy efficiency, and low labor costs. Its ability to produce strong, hermetic seals without compromising the integrity of the components makes it a preferred choice for industries where product safety and quality are paramount.

Choosing the Right Ultrasonic Welding Machine

Selecting the appropriate ultrasonic welding system involves understanding the specific requirements of the task at hand. Factors such as the type of materials to be welded, the complexity of the components, and the production volume should guide the decision-making process. While Alibaba.com does not endorse any particular brand or model, the platform offers a diverse array of options to cater to these varied needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4