Popular in your industry

Related Searches:

Top categories

About 5 ton die cutting press

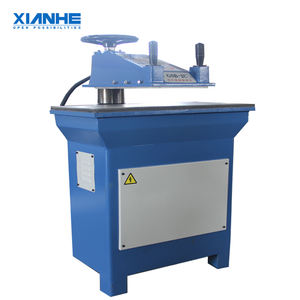

Introduction to 5 Ton Die Cutting Press

Die cutting presses are essential tools in the manufacturing sector, and a 5 ton die cutting press is particularly versatile for medium-scale production. This type of machinery is adept at shaping and cutting materials with precision, making it a staple in the production of paper goods such as toilet papers and napkins.

Types and Applications

The die cutting machine comes in various configurations to meet diverse industry needs. From hospitality to paper processing plants, these machines streamline the production of paper cups, serviettes, and tissues. The adaptability of a 5 ton die cutting press allows for its use in a range of settings, tailoring its operation to the scale of production required.

Features and Technical Specifications

A typical die cutting press integrates multiple units for embossing, slitting, and folding, ensuring a seamless production line. The embossing unit can feature different patterns, utilizing steel-to-steel or steel-to-rubber mechanisms. With production capacities varying, a smaller die cutting press might produce 70 to 80 pieces per minute, while larger counterparts can handle up to 150 meters of material per minute.

These presses are engineered for efficiency, with some models incorporating gear or chain driving systems. Automation is a key feature, with many machines boasting automatic oil lubrication and photoelectric technology for operational monitoring.

Materials and Construction

The construction of a 5 ton die cutting press is robust, often involving heavy-duty materials to withstand the rigors of continuous operation. The weight and power usage of these machines can vary, with smaller units starting at around 1,000 kilograms and using upwards of 3kw of power.

Advantages of Using a 5 Ton Die Cutting Press

The main advantage of utilizing a 5 ton die cutting press is its balance between size and capability. It's an optimal solution for businesses looking to scale up their production without committing to the space and expense of larger machinery. The integration of a PLC control panel in many models translates to user-friendly operation and automation, enhancing productivity and reducing the need for constant manual oversight.

Operational Efficiency and Safety

Operational efficiency is paramount in die cutting presses, with many models featuring pneumatic systems powered by an air compressor. Safety is also a critical aspect, with machines equipped with alarms to alert operators to paper shortages or operational issues, ensuring a smooth and safe production process.