Popular in your industry

Related Searches:

Top categories

About 6mm carbon fiber plate

In the vanguard of industrial innovation, 6mm carbon fiber plates stand as a paragon of efficiency and strength. These marvels of modern engineering are crafted from carbon atoms bonded in crystalline formations, yielding unparalleled stiffness and lightness. This guide delves into the essence of carbon fiber plates, elucidating their composition, characteristics, and the transformative impact they have across diverse industries. From aerospace to robotics, carbon fiber's superior strength-to-weight ratio and durability are reshaping manufacturing paradigms, offering a glimpse into the future of advanced material applications.

Understanding Carbon Fiber Plates

Carbon fiber plates are crafted from carbon atoms bonded together in crystalline formations, creating filaments known for their impressive stiffness, strength, and lightness. These plates are typically made from strands or yarns termed 'Tows' and are available in various forms such as spools, unidirectional formats, weaves, and braids. The production of carbon fiber involves complex processes, starting with spinning a precursor material like polyacrylonitrile (PAN), pitch, or rayon into fibers. These fibers undergo stabilization in an oxygen-free environment to prevent burning or shrinking, followed by carbonization at extremely high temperatures to remove non-carbon elements, resulting in a nearly pure carbon crystalline structure. A surface treatment is then applied to enhance adhesion to matrix materials before the fibers are wound onto spools.

To fabricate carbon fiber composite parts, the carbon fibers are embedded within a matrix, typically epoxy resin, to maintain shape and add stability. The combination of low-density epoxy and carbon fibers results in a lightweight yet robust component. The mechanical properties of these composites, such as stiffness and strength, are influenced by the fiber and resin properties, fiber placement and orientation, and the fiber/resin ratio. Carbon fiber's modulus of elasticity, a measure of stiffness, is typically 33 msi (228 Gpa), and its ultimate tensile strength is around 500 ksi (3.5 Gpa). These properties make carbon fiber plates highly sought after in applications requiring superior strength-to-weight ratios.

The Evolution of Carbon Fiber in Industrial Applications

Carbon fiber has undergone significant evolution in industrial applications since its serendipitous discovery in the mid-20th century. Initial developments aimed at enhancing the carbon content of fibers led to the creation of high-performance materials that captured the attention of various industries. By the 1970s, carbon fiber products began to be integrated into sports equipment, marking the beginning of widespread commercial use. The following decade saw carbon fibers being adopted by the aerospace sector, with production capacities expanding to meet the growing demand.

The 1990s and early 21st century were particularly notable for the integration of carbon fiber composites in aerospace applications, with major aircraft manufacturers showcasing the material's benefits in commercial aircraft. This period also witnessed the diversification of carbon fiber use into the automotive and wind energy sectors, driven by the material's exceptional strength-to-weight and stiffness-to-weight ratios. Technological advancements have further broadened the applications of carbon fiber, making it a key component in modern engineering and manufacturing.

Recent innovations have focused on reducing costs and improving the performance of carbon fiber composites. Developments in manufacturing techniques, such as filament winding and pultrusion, have been instrumental in enhancing production efficiency. The industry has also seen a shift towards more sustainable practices, with recycling and reusing carbon fiber composites becoming a priority to address environmental concerns. These advancements underscore the ongoing commitment to expanding the capabilities and applications of carbon fiber in various industrial sectors.

6mm Carbon Fiber Plates: Composition and Characteristics

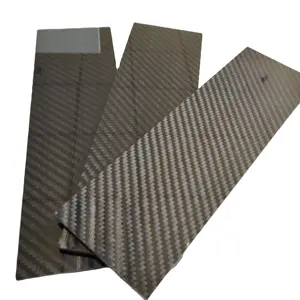

6mm carbon fiber plates are engineered from carbon atoms bonded together in a crystalline formation, creating filaments known as 'Tows'. These tows are then woven, braided, or aligned unidirectionally to form various carbon fiber formats. The typical carbon fiber used in these plates originates from polyacrylonitrile (PAN), pitch, or rayon. Through a meticulous process involving spinning, stabilization in an oxygen-free environment, and carbonization at temperatures up to 3000 degrees Celsius, the fibers achieve a high strength-to-weight ratio. A surface treatment is applied to enhance adhesion to matrix materials like epoxy resin, which supports the carbon fibers in the composite structure. The resulting 6mm plates exhibit remarkable stiffness and strength, attributable to the material's inherent properties and the precision of fiber placement and orientation within the resin matrix.

Advantages of Using 6mm Carbon Fiber Plates

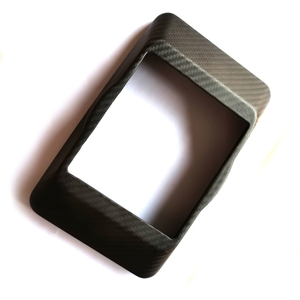

The 6mm carbon fiber plates are crafted using carbon fiber reinforcement and epoxy, resulting in sheets that are not only structurally sound but also exhibit a smooth, pinhole-free finish on both sides. This construction technique ensures a quasi-isotropic fiber orientation, which means the carbon fiber sheets have been layered in a way that strength is uniformly distributed. This specific orientation enhances stiffness across the diagonal axis and significantly improves torsional stiffness.

These carbon fiber plates are made with an epoxy resin known for its excellent mechanical properties, clarity, and UV stability, although additional UV protection is recommended to maintain the finish. The manufacturing process includes an elevated post-cure temperature, which boosts the mechanical strength of the panel. This treatment results in a higher Tg (glass transition temperature), which in turn enhances the inter-laminar shear strength of the plates.

The dual-sided gloss finish of the sheets is achieved using a 2x2 3k woven carbon fiber fabric, and to preserve the pristine condition during transport, the sheets are coated with a protective film. These attributes make the 6mm carbon fiber plates suitable for applications that demand both structural integrity and an aesthetically pleasing appearance.

Strength-to-Weight Ratio and Durability

Carbon fiber is renowned for its exceptional strength-to-weight ratio, a key characteristic that makes it a material of choice for various demanding applications. The fibers are engineered to deliver performance where the balance between strength and weight is critical. The modulus of these fibers, indicating their stiffness, is in the range of 33-34 Msi, which is indicative of their ability to withstand force without deformation. This balance of tensile strength and modulus contributes to the durability and longevity of carbon fiber products, making them suitable for use in environments where other materials might fail. The availability of these fibers in various tow sizes allows for versatility in their application, ensuring that they can be adapted to meet the specific strength and durability requirements of different industrial tasks.

Corrosion Resistance and Longevity

Carbon fiber's resistance to corrosion stands out as a significant advantage, especially when compared to traditional materials like metal. Its unique composition, featuring a carbon fiber reinforced polymer (CFRP), offers exceptional durability and longevity. The epoxy resin within CFRP is inert, meaning it does not react to environmental factors that typically cause corrosion or rust. This inherent resistance extends the lifespan of carbon fiber components, making them a reliable choice for long-term applications.

Furthermore, carbon fiber maintains its integrity against oxidization due to the robust carbon bonds in the fibers. Unlike metals, which can expand, weaken, or even fail when exposed to heat, carbon fiber exhibits low thermal expansion. This stability under varying temperatures contributes to its durability and suitability for use in environments where thermal stability is crucial. Additionally, its low thermal conductivity means that it does not easily transmit heat, further preserving its structure and function over time.

Applications in Various Industries

Carbon fiber's exceptional strength and rigidity have made it a material of choice across various industries. Its high strength-to-weight and stiffness-to-weight ratios are particularly valued in the aerospace sector, where every gram counts. The material's versatility extends to the production of drones, construction materials, robotics, and even sporting goods, leveraging its lightweight yet robust nature.

The medical field benefits from carbon fiber's biocompatibility and radiolucency, making it suitable for prosthetics, implants, and surgical instruments. Its low thermal expansion properties are critical in the manufacturing of medical imaging tables, which remain dimensionally stable under radiation. Similarly, precision instruments like telescopes and optical benches rely on carbon fiber for its minimal thermal expansion.

In the realm of music, carbon fiber is appreciated for its ability to enhance instrument resonance, offering a full sound and consistent performance regardless of humidity changes. The material's low damping to vibration, coupled with its high stiffness, contributes to superior acoustic properties.

The manufacturing industry also harnesses carbon fiber for creating lighter, more efficient tools. Carbon fiber composites can significantly reduce the weight of tools and machine parts, facilitating easier handling and movement. For instance, carbon fiber idler rolls outperform steel by being more rigid, which minimizes bending and allows for faster production speeds with less energy consumption.

Aerospace and Automotive Innovations

Advanced composite materials, particularly carbon fiber reinforced polymer (CFRP), are revolutionizing the aerospace and automotive industries. Their exceptional strength and lightweight nature contribute significantly to performance enhancements. In aerospace, CFRP is integral to aircraft structures, such as fuselages, wings, and tail sections, facilitating weight reduction and fuel efficiency improvements over traditional materials like aluminum. The automotive sector also benefits from CFRP, utilizing it in body panels, chassis components, and wheels to decrease weight, which leads to better fuel efficiency and handling. The innovation in composite materials, driven by industry leaders, continues to open new possibilities for their application, promising further advancements and efficiency in aerospace and automotive design.

Robotics and Engineering Complexities

Facilities that integrate industrial automation and robotics are constantly seeking ways to enhance efficiency by optimizing speed and precision. A key strategy to achieve these improvements is by reducing the weight and increasing the stiffness of robotic components, especially end effectors. Lightweight end effectors can lead to faster production line speeds, heightened precision, and reduced strain on motors and actuators, contributing to overall reliability. Carbon fiber composites are particularly beneficial in these applications due to their significant weight reductions compared to traditional metal parts.

In the realm of robotics and engineering, carbon fiber materials offer a versatile range of options for designers. Basic structural components such as flat sheets, angles, and tubes can be utilized to create lightweight yet robust end effectors. These components can be seamlessly integrated into existing manufacturing lines, often with minimal modifications required. The use of advanced connection systems allows for the construction of strong, lightweight frames and trusses, which are essential in complex robotic applications.

The design and production of specialized robotics and automation end effectors are supported by technologies such as finite element analysis and CAD design. Custom components and assemblies can be crafted to meet specific requirements, leveraging materials like carbon fiber and Kevlar to achieve the desired performance characteristics. For high-temperature applications, certain carbon fiber composites can withstand extreme temperatures without significant loss of stiffness, making them suitable for use in environments that challenge other materials.

Purchasing 6mm Carbon Fiber Plates on Alibaba.com

When considering the acquisition of 6mm carbon fiber plates, Alibaba.com stands out as a significant marketplace that caters to a diverse range of industrial needs. The platform offers an extensive selection of carbon fiber plates, including options that vary in size, thickness, and weave patterns, such as plain or twill. These plates are available in dimensions like 400mm x 500mm, with thickness options extending from 0.3mm to 10mm, ensuring that buyers can find the exact specifications required for their projects.

The variety of carbon fiber plates on Alibaba.com includes those with specific features like CNC cutting services, which allows for precision customization to meet intricate design requirements. This is particularly beneficial for industries that require unique shapes and sizes for their components. Additionally, the platform lists products from manufacturers that offer different grades of carbon fiber, such as T700, T800, and M40, providing purchasers with the flexibility to choose based on strength, stiffness, and budget considerations.

For businesses looking to place bulk orders, Alibaba.com provides access to suppliers who can accommodate large quantities with consistent quality. This is crucial for large-scale applications where uniformity in material properties is essential. The site's interface facilitates easy communication with suppliers, enabling buyers to discuss customization options, such as specific fiber alignments, resin types, and surface finishes, ranging from glossy to matte, to suit their application needs.

Selecting the Right Supplier for Your Needs

When considering a supplier for carbon fiber plates, it's essential to select one that offers a blend of expertise and customization. Alibaba's own network of trusted suppliers provides carbon fiber sheets tailored to specific applications, ensuring that the parts meet precise specifications.

The engineering teams within Alibaba's supplier network are willing to collaborate closely with clients to deliver parts that not only fit the application but also contribute to overall performance. This collaborative approach is crucial for industries that require unique solutions for automation robotics, aerospace, or other specialized fields.

A supplier's proficiency in the composites industry, from materials science to the manufacturability of components, is a significant consideration. The ability to provide cost-effective composite products through innovative engineering and advanced manufacturing technologies can be a deciding factor. Moreover, the availability of a variety of stock products for direct shipping can be beneficial for immediate needs.

Customization and Bulk Ordering

Our facility is equipped to handle custom orders, ensuring that each carbon fiber part meets specific design and performance characteristics, even for the most challenging projects. With a range of thicknesses available, we can accommodate custom sheet requirements up to 1 inch, including the sought-after 6mm carbon fiber plates. Our in-house machining team is adept at precise cuts, maintaining a tight tolerance to ensure a perfect fit for your applications.

For those looking to secure their carbon fiber components, we offer a selection of adhesives. Among these, a high-performance, high-temperature double-adhesive film is available, capable of withstanding significant heat, ensuring durability and stability in various applications. This selection allows for a clean application process, contributing to the overall integrity and performance of the final product.

We cater to bulk ordering needs with a commitment to consistency and detail. Our manufacturing process, designed to handle large-scale production, ensures that each replicated part maintains the same level of precision and quality as the original prototype. This systematic approach to production is ideal for clients who require high volumes of carbon fiber plates, including the versatile 6mm variant, for their industrial applications.

Conclusion

In conclusion, 6mm carbon fiber plates represent a significant leap forward in material science, offering a combination of strength, stiffness, and lightweight properties that are unmatched by traditional materials. Their resistance to corrosion, high thermal stability, and exceptional durability make them ideal for a wide range of industrial applications, from aerospace and automotive to robotics and medical equipment. The evolution of carbon fiber in industrial use underscores a commitment to innovation and efficiency, with ongoing advancements promising to further expand its applications. When sourcing these materials, platforms like Alibaba.com provide a vast selection, ensuring that businesses can find the exact specifications they need. Suppliers on Alibaba offer the expertise and customization necessary to meet the most demanding requirements. As industries continue to seek out performance-enhancing materials, the role of carbon fiber, particularly the versatile 6mm plates, is set to grow, marking a new era of industrial capability and design.