Popular in your industry

Related Searches:

Top categories

About thread rolling machines

What are Thread Rolling Machines

Thread rolling machines are specialized mechanical devices designed to produce precise threads on a variety of materials, including metal, plastic, and wood. These machines serve an essential role in the manufacturing industry, especially for companies involved in the production of fasteners, screws, and bolts or those that require threaded components in machinery. The principle behind thread rolling is to form threads by displacing material using a cold-forming process as opposed to cutting or removing material.

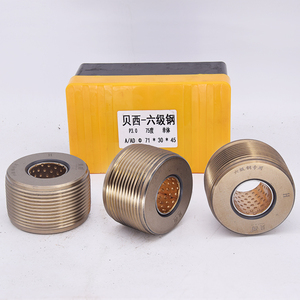

This process starts with a blank workpiece that is typically at the diameter of the thread's minor diameter. The workpiece is then placed between dies that have the reverse profile of the thread to be formed. As the dies rotate and/or move together, they exert pressure on the surface of the blank, causing the material to flow and form into the shape of the dies. This method not only produces threads quickly but also enhances their strength due to work hardening and an uninterrupted grain flow within the material.

Thread rolling machines can come in various forms, from simple hand-operated devices to complex, fully automated systems. One significant advantage of thread rolling over traditional cutting methods is that it produces stronger, more fatigue-resistant threads and tends to be more efficient and cost-effective, especially for high-volume production. Moreover, since there is no material waste during the process, it's considered environmentally friendly and economical.

Types of Thread Rolling Machines

Within the realm of thread rolling machines, several types are available to cater to different production requirements and workpiece sizes. Each type possesses unique characteristics that make it suitable for specific applications:

Flat Die Thread Rolling Machines: These machines use flat dies with threaded profiles. One die is stationary while the other slides to roll the thread onto a workpiece. Flat die thread rollers are commonly used for threading long rods or bolts and can be employed for both in-feed (plunge rolling) and thru-feed rolling processes.

Cylindrical Die Thread Rolling Machines: In these machines, two or three cylindrical dies with helical threads encircle the workpiece to form threads. They are well-suited for mass production of screws and bolts and offer excellent precision and speed.

Planetary Thread Rolling Machines: Also known as rotary thread rolling machines, these devices use a fixed die plate with several moving dies that rotate around the workpiece in a planetary manner. This type is highly efficient for producing threads on small parts like screws or pins at very high speeds.

Each type has its own set of advantages and common use cases which can be matched according to production needs.

How to choose Thread Rolling Machines

Selecting the appropriate thread rolling machine is crucial for ensuring efficiency, precision, and cost-effectiveness in your manufacturing operations. Here are some key considerations businesses should take into account:

Thread Specification: Consideration should be given to thread size, pitch, and profile since different machines accommodate various ranges of these specifications.

Volume Requirements: High-volume production may necessitate an automated cylindrical die machine while lower volumes or speciality threading could be suited to a flat die machine.

Material Type: The type of material being threaded (metallic or non-metallic) can influence machine choice due to differences in force requirements and material properties.

Machine Versatility: Some businesses require machines that can handle multiple operations or sizes which means looking for multi-functional or easily adjustable machines.

After-sales Service: Comprehensive technical support and availability of engineers for service overseas can be crucial factors for businesses operating in remote regions or with limited local expertise.

Considering these factors can guide businesses in making an informed decision when investing in thread rolling machinery on Alibaba.com.

Best Thread Rolling Machines on Alibaba.com

For businesses looking for reliable thread rolling machines that bring efficiency and precision to their production lines, Alibaba.com stands out as an exemplary marketplace. As one of the largest B2B platforms globally, it connects buyers with a multitude of suppliers offering a wide variety of equipment suitable for all industrial needs. Whether your business specializes in construction materials or you handle intricate machinery manufacturing, you'll find a thread rolling machine that meets your requirements on Alibaba.com.

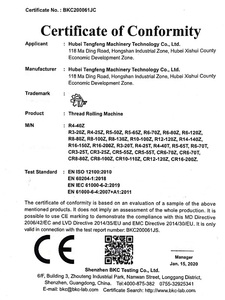

This platform excels not just in variety but also in convenience. With just a few clicks, buyers can navigate through detailed product listings with machinery test reports, compare key selling points like ease of operation and maintenance costs, and even review after-sales services provided by suppliers worldwide. Alibaba.com simplifies international trade by offering services like Trade Assurance which protects buyers throughout their transactions ensuring peace of mind when procuring industrial machinery from suppliers across different continents.

Alibaba.com's commitment to serving small and medium-sized businesses around the world is evident through its easy-to-use interface available both on mobile devices and desktops. With features that support buying in local languages and dedicated customer service teams ready to assist at every step, Alibaba.com ensures that obtaining high-quality industrial equipment like thread rolling machines is seamless for businesses everywhere.

Common FAQs for Thread Rolling Machines

What is a thread rolling machine and how does it differ from thread cutting?

A thread rolling machine forms threads by displacing and flowing material into the desired shape without removing any material, which strengthens the thread. In contrast, thread cutting removes material to create the thread profile, which can weaken the thread.

What types of thread rolling machines are available?

The main types of thread rolling machines include flat die, cylindrical die, and planetary (rotary) thread rolling machines, each suited to different production volumes and types of threads.

Which industries commonly use thread rolling machines?

Industries that commonly use thread rolling machines include manufacturing plants, building material shops, machinery repair shops, and anywhere that requires the production of threaded components like fasteners and bolts.

Can thread rolling machines work with various materials?

Yes, thread rolling machines can work with a range of materials including metals, plastics, and wood. However, the choice of machine may depend on the specific material properties.

What are the key benefits of using a thread rolling machine?

Key benefits include stronger threads due to work hardening, higher production rates, no material wastage, and threads with excellent surface finish and dimensional accuracy.

How do I choose the right thread rolling machine for my business?

Consider the specific threads you need to produce (size, pitch), your volume requirements, material types, machine versatility, and after-sales service options when choosing a machine for your business.

Can thread rolling machines handle different thread sizes and pitches?

Yes, many thread rolling machines are adjustable or come with interchangeable dies to accommodate various sizes and pitches of threads.

Is it possible to obtain machinery test reports for thread rolling machines on Alibaba.com?

Yes, product listings on Alibaba.com often include machinery test reports provided by suppliers which can be reviewed before making a purchase decision.

What after-sales services are commonly provided with thread rolling machines?

Common after-sales services for these machines include video technical support, online support, and engineers available to service machinery overseas.

How does Alibaba.com ensure the quality of thread rolling machines sold on its platform?

Alibaba.com offers Trade Assurance which protects buyers' payments until delivery is confirmed and ensures that transactions are secure. Buyers can also review supplier ratings and customer feedback on the platform.