Popular in your industry

Related Searches:

Top categories

About blanking punch and die

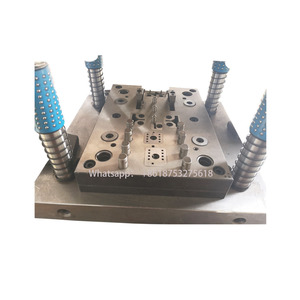

Introduction to Blanking Punch and Die

The blanking punch and die set is an essential component in the manufacturing industry, designed for cutting out parts from various materials. This process, known as blanking, is a subset of the punching operations which also includes punching blanking piercing. The precise nature of these tools allows for the creation of parts with exact dimensions and smooth edges, which are crucial for the subsequent assembly processes.

Types and Applications

There are various types of blanking dies and punches, each tailored for specific applications and materials. The choice of a blanking die depends on factors such as the material's thickness and the complexity of the part's shape. These tools are widely used in industries ranging from automotive to electronics, where they facilitate the mass production of consistent and uniform components.

Features and Materials

The materials used for blanking punches and dies must possess high wear resistance and toughness to withstand the stress of cutting. Common materials include tool steels and carbides, which are selected based on the material to be punched and the expected lifespan of the tool. Features such as the punch-to-die clearance are meticulously calculated to ensure optimal cutting with minimal burring.

Advantages of Precision Tooling

Utilizing a blanking punch and die offers several advantages, including increased efficiency and the ability to maintain tight tolerances. The repeatability of the process ensures that each component is virtually identical, which is critical for automated assembly lines. Additionally, the standardization of components like lift bars and clamp slots can streamline the manufacturing process, enhancing overall productivity.

Selection Considerations

Selecting the right blanking punch and die involves understanding the specific requirements of the task at hand. Factors such as material type, thickness, and the complexity of the part design play a crucial role in determining the appropriate tooling. Suppliers on Alibaba.com offer a diverse range of options, enabling buyers to find the right match for their manufacturing needs without the constraints of a one-size-fits-all approach.

Optimizing Production with the Right Tools

In conclusion, the right set of blanking punches and dies is pivotal for optimizing production lines and achieving efficient manufacturing cycles. Alibaba.com serves as a gateway for businesses to connect with suppliers that can provide the necessary tooling to meet their specific blanking requirements. By leveraging the platform's extensive network, buyers can source the ideal tools to enhance their production capabilities.