Popular in your industry

Related Searches:

Top categories

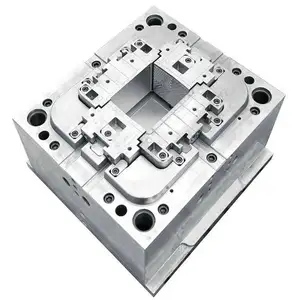

About blister mould

An Overview of Blister Mold Design

An indispensable tool for those in the manufacturing sector, a blister mold design guide is crucial for creating blister packs—a prevalent packaging solution that safeguards and showcases a diverse array of products. These packs, often crafted from plastics like PVC, PET, or PP, are ubiquitous in the pharmaceutical, consumer goods, and electronics industries. A blister pack is characterized by a pre-formed plastic cavity that encloses the product and a sealable backing material that forms a protective bubble around it.

The guide's primary role is to facilitate the design of blister packs by offering detailed specifications for the mold's configuration and measurements. It considers elements such as the type of material, the necessity for product visibility, and design intricacy to ensure the end product adheres to the application's unique demands. Moreover, the guide elucidates the operational principles of blister molds, which is essential for refining the manufacturing process and circumventing problems like excess material or damage to the product.

Blister molds employ the straightforward technique of vacuum forming. A heated plastic sheet is molded over a template to form the blister. Once the product is positioned within the cavity, the air is removed, allowing the plastic to cool and solidify. The mold's design must be exact to produce the intended shape, consistency, and distribution of material for the blister, while also guaranteeing that the final product can be effortlessly detached from the backing for packaging.

Varieties of Blister Mold Designs

Blister packaging encompasses a spectrum of mold types, each tailored to meet particular industry needs. Below is an exploration of some common variants:

-

Thermoforming Molds: Employed to shape blisters by softening a plastic sheet with heat and then using a vacuum to form it into the desired contour. These are optimal for crafting bespoke shapes for distinctive items like electronics or consumer products.

-

Cold Forming Molds: This technique shapes a blister in a non-heated setting, enabling the creation of intricate forms. These molds are frequently utilized in the pharmaceutical industry for encapsulating tablets and capsules.

-

Rubber and Silicone Molds: These pliant molds are crafted from rubber or silicone and are adept at producing unconventional blister shapes. They are especially valuable for prototype development or limited production runs due to their versatility and user-friendliness.

-

Steel Rule Dies: These dies are designed for hand-operated or small-scale production, cutting or scoring a material sheet into the required configuration. They are often employed in crafting or for display purposes at points of sale.

-

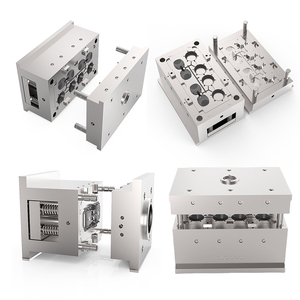

Digital Molds (CNC Machining): Molds produced with CNC machining offer unparalleled precision and consistency with minimal manual intervention, making them suitable for mass production in sectors like food packaging.

Each mold type is chosen based on industry-specific criteria, such as the required precision level and the production volume.

Selecting a Blister Mold Design Guide

Choosing the appropriate blister mold design necessitates a thorough assessment of various factors that correspond with your enterprise's particular needs and the products you intend to package. Consider the following:

-

Material Compatibility: Your choice of mold design will be influenced by the material you intend to use—be it PVC, PET, or another plastic. Certain materials may demand specialized molds with features like UV resistance or biodegradability.

-

Production Volume: The scale of your production will determine whether a standard mold capable of handling large volumes is appropriate, or if a bespoke mold that accommodates unique shapes and sizes is preferable.

-

Product Complexity: Products with more complex shapes or designs might require custom molds that can capture finer details or be shaped with greater precision.

-

Regulatory Compliance: It's imperative to ensure that any mold design under consideration complies with industry-specific regulations, especially those related to safety and environmental impact.

Exploring Blister Mold Design Guides on Alibaba.com

Alibaba.com distinguishes itself as a global marketplace that bridges businesses with an extensive array of blister mold designs, catering to various industries. Whether you represent the pharmaceutical industry in search of standard pill blister packs or a food retailer in need of distinctive meal tray designs, Alibaba.com offers a comprehensive catalog of choices from suppliers worldwide.

The platform's intuitive interface streamlines the search for the ideal blister molds, enabling users to filter options by material type, core components, service location, and even unique selling propositions such as eco-friendliness or enhanced productivity. Alibaba.com also provides buyer support with services like Trade Assurance, guaranteeing secure transactions and the fulfillment of orders as anticipated.

Opting for Alibaba.com for your blister mold design needs grants access to a trove of expertise and resources that can bolster your business's growth. With its dedication to providing straightforward access to global trade solutions, Alibaba.com equips businesses to find precisely what they require while enjoying competitive prices and potential customization opportunities from various suppliers on the platform.

Frequently Asked Questions on Blister Mold Design

What constitutes a blister mold?

A blister mold is a specialized tool for fabricating tailor-made blister packs for items like pharmaceuticals, electronics, or collectibles. It features a mold cavity bordered by two material sheets, with a forming area on one side and a flat backing on the other. The mold is inserted into a thermoforming machine, which heats the material and then employs a vacuum to shape it accordingly.

Is it possible to use blister molds for food packaging?

Certainly, blister molds are apt for packaging food items, including produce and meats, as long as they are constructed from food-safe materials and designed to fulfill the specific demands of food packaging.

Are there environmentally friendly options for blister molds?

Environmentally conscious blister molds are indeed available, crafted from materials that are either biodegradable or recyclable. These alternatives are particularly attractive to companies prioritizing sustainability and ecological stewardship.

How should I select the appropriate material for my blister mold?

Selecting the ideal material for your blister mold requires evaluating aspects such as the nature of the product being packaged, compatibility with the contents, desired shelf life, and environmental considerations. Commonly utilized materials include PVC, PET, and PP.

What are the principal considerations when designing a blister mold?

Crucial considerations in designing a blister mold encompass the product's shape and size, the volume of blister packs needed, material specifications, the level of product protection required, and the intended application of the final package.

Can blister molds be tailored to fit my product's specific shape and size?

Yes, blister molds can be extensively customized to suit a variety of shapes and sizes, ensuring an exact fit for your product and meeting particular display needs.

What differentiates thermoforming from vacuum forming in blister mold design?

Thermoforming is the process of heating a material sheet until pliable and then shaping it, whereas vacuum forming involves drawing heated air over the material to conform it to the mold's surface. Each technique is selected based on the design requirements.

How does material choice impact the cost of a blister mold?

The selection of material can have a significant impact on the cost of a blister mold. Materials like PVC are generally economical and widely used, while alternatives such as PP and PET provide durability and clarity but may come at a higher cost.

What is the expected lifespan of a blister mold?

The lifespan of a blister mold is contingent upon variables like usage frequency, maintenance practices, and the material's resistance to wear. With appropriate care, a well-crafted mold can endure thousands of cycles.

Are blister molds suitable for heavy items or liquids?

Blister molds are typically employed for lightweight items that need display or protection, as well as for securing delicate products. The appropriateness of a blister mold for heavy items hinges on the strength of the material and the design of the package.

What maintenance is required for a blister mold to ensure its longevity?

Maintaining a blister mold's longevity involves regular cleaning with suitable agents and proper storage when not in use.

Are there any industry standards for blister mold design that I should know?

While universal industry standards may not exist, it is crucial to comply with any pertinent regulations or standards related to your product's market to ensure safety and conformity.

How does the proximity of a service location affect the choice of a blister mold?

Selecting a supplier with a nearby service location can offer advantages such as quicker order processing, lower shipping costs, and more straightforward communication. It also simplifies maintenance and troubleshooting if necessary.