Introduction to Busbar Punching Machines

Busbar punching machines are specialized pieces of industrial equipment designed for processing busbars, which are thick strips of copper or aluminum used for conducting electricity within a switchboard, distribution board, substation, or other electrical apparatus. These machines streamline the manufacturing process by integrating multiple functions such as punching, shearing, and bending, enhancing the efficiency of metalwork fabrication.

Functional Diversity and Applications

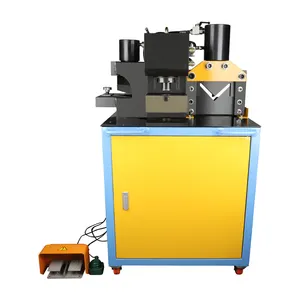

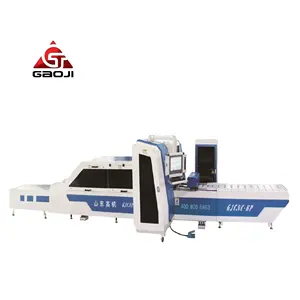

The versatility of a busbar processing machine lies in its multifunctional capabilities. Equipped to handle embossing, shearing, slotting, and round cornering, these machines serve as a comprehensive solution for metalworking tasks. Their application is widespread across electrical switchboard manufacturing and in settings requiring rapid and precise metal forming, such as in factory production lines.

Technical Specifications and Features

Precision is paramount in busbar fabrication, and modern busbar fabrication equipment is designed with linear guides and high-precision ball screws to ensure accuracy. The integration of a spring system in the accessory connections mitigates overheating risks and simplifies maintenance by reducing the need for hardware tightening. Additionally, the incorporation of hydraulic systems empowers these machines to manipulate heavy metal bars effortlessly.

Materials and Durability

Durability is a critical aspect of busbar punching machines, with construction from materials that resist corrosion and wear. The use of retardant materials not only extends the lifespan of the equipment but also ensures consistent performance in demanding industrial environments. This resilience is crucial for factories prioritizing longevity and reliability in their equipment investments.

Design and Customization

A busbar machine comes in various sizes, shapes, and colors, catering to diverse industrial needs and preferences. The design of these machines often emphasizes ease of use, negating the need for extensive training. Operators can expect straightforward interfaces, with automated systems requiring minimal input to commence complex metalworking tasks.

Operational Efficiency

The operational efficiency of a busbar punching and cutting machine is a significant advantage for industrial users. Automation is at the heart of these machines, allowing for simple start-stop operation and the ability to handle high-volume production with ease. Such efficiency is essential for businesses looking to scale up production without compromising on the quality or precision of the output.

In summary, the busbar punching machine category on Alibaba.com encompasses a range of equipment tailored for efficient and precise busbar processing. While exploring the options available, buyers can consider the technical specifications, design elements, and operational features that align with their industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4