Exploring Automated Chicken Cutlet Makers

Automated chicken cutlet makers are state-of-the-art food processing devices that enhance the efficiency of chicken cutlet production. These machines are indispensable in the food sector, especially for enterprises that demand uniform portioning and shaping of chicken fare. Their utility spans from modest delis and butcher shops to expansive poultry farms and food production companies.

At the heart of automated chicken cutlet makers lies the dual promise of precision and efficiency. They revolutionize the conventional cutlet preparation steps—portioning, shaping, breading, and sometimes frying—through automation. Cutting-edge technologies are harnessed to guarantee that each cutlet is consistent in size and shape, a key factor for both aesthetic appeal and even cooking.

Designed to boost productivity and give operators more control, these machines often feature adjustable settings for meat thickness, allowing for customization to meet specific culinary demands. Many models also boast intuitive interfaces, enabling users to fine-tune parameters such as portion size, shape, and breading choices.

Varieties of Automated Chicken Cutlet Makers

Diverse automated chicken cutlet makers serve different production volumes and the particular needs of food service providers. Below are some prevalent types:

-

Handheld Chicken Cutlet Maker: These small, mobile units are perfect for limited use or domestic kitchens, often incorporating a ratchet system for precise control over cutlet thickness. Ideal for quaint eateries or personal culinary experiments.

-

Automatic Chicken Cutlet Maker: These are motorized, programmable units capable of handling substantial quantities, commonly found in commercial environments like restaurants and catering services. They can churn out hundreds of identical cutlets hourly, thus reducing time and labor expenses.

-

Electric Chicken Cutlet Maker with Tenderizer Function: This versatile appliance merges cutting and tenderizing capabilities, proving especially beneficial for dishes that require a tender yet flavorful bite.

-

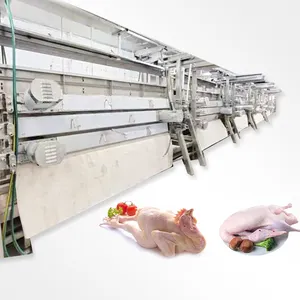

Industrial Chicken Cutlet Production Line: Suited for operations with intensive demands such as large-scale food service or processing facilities, these comprehensive lines integrate several machines to mass-produce cutlets, often including battering, breading, and packaging stations.

Selecting the Right Automated Chicken Cutlet Maker

Choosing an appropriate Automated Chicken Cutlet Maker is critical for businesses aiming to enhance efficiency while maintaining food safety and quality. Consider the following when making your selection:

-

Production Output: The initial step is to evaluate the quantity of chicken cutlets your operation requires. Machines like the NexGen Cutlet Maker are engineered for high-output environments.

-

Cutlet Type and Size: Identify the specific cutlet variety you wish to produce—be it standard, minced, or schnitzel—and opt for a machine that can accommodate the desired dimensions.

-

Cut Quality: Given that the quality of cutlets can influence customer satisfaction and cost management, prioritize machines with a track record of consistent performance.

-

Food Safety Standards: Verify that the machine adheres to pertinent food safety regulations and your own quality benchmarks.

-

Maintenance Requirements: Factor in the ease of cleaning and upkeep for the machine. Models that demand minimal maintenance will reduce time and labor costs over time.

By weighing these elements, businesses can make a well-informed choice in acquiring an Automated Chicken Cutlet Maker that meets their operational exigencies and quality criteria.

Automated Chicken Cutlet Makers on Alibaba.com

Alibaba.com distinguishes itself as a premier global marketplace, linking businesses with a broad spectrum of suppliers that provide automated chicken cutlet makers for diverse operational requirements. The platform accommodates a variety of production needs and industry specifications, from petite food outlets to extensive manufacturing operations, ensuring buyers can secure the ideal solution for their existing workflows.

A key benefit of sourcing from Alibaba.com is the plethora of choices on offer. The platform showcases machines featuring core components like motors and gearboxes from reputable global suppliers. This assortment not only enables businesses to locate machines that fulfill their particular demands but also allows for bespoke adaptations to meet unique needs.

The commitment of Alibaba.com to fostering international commerce is manifest in its accessible interface that supports multiple local languages and mobile use. Additional services such as Trade Assurance bolster transaction security by safeguarding payments until delivery confirmation. With its extensive product range and dedication to secure trading, Alibaba.com is an exemplary resource for firms seeking to upgrade their production lines with automated solutions.

Frequently Asked Questions About Automated Chicken Cutlet Makers

What is the role of an automated chicken cutlet maker in a commercial context?

In commercial settings, an automated chicken cutlet maker is instrumental in mass-producing chicken cutlets with uniform quality, benefiting entities like fast-food franchises, large dining establishments, and food production companies.

How does an automated chicken cutlet maker function?

An automated chicken cutlet maker typically relies on a sequence of blades to carve meat into predetermined shapes and sizes, adhering to pre-set patterns for maximum efficiency and uniformity.

Is it possible to tailor automated chicken cutlet makers for specific shapes and sizes?

Certainly, numerous automated chicken cutlet makers are equipped with modifiable settings or replaceable blades to cater to various chicken cutlet dimensions and forms.

What considerations are important when selecting a supplier for an automated chicken cutlet maker?

Key considerations when choosing a supplier for an automated chicken cutlet maker include the quality of the machine, the diversity of shapes it can produce, the construction material, and the extent of customer support post-purchase.

Are automated chicken cutlet makers appropriate for small-scale production?

Automated chicken cutlet makers are well-suited for businesses that prioritize uniform quality and substantial production volumes, making them apt for both large and smaller enterprises.

What is the typical duration for cleaning and maintaining an automated chicken cutlet maker?

The time needed to clean and maintain an automated chicken cutlet maker varies with the design and settings of the machine. Generally, these machines are crafted for straightforward maintenance and should be cleaned as per the manufacturer's guidelines.

Can I locate a local service center for my automated chicken cutlet maker on Alibaba.com?

While Alibaba.com is a conduit for online transactions, it is advisable to utilize the platform's search filters to find suppliers that provide local service centers if needed for your business.

Is obtaining a machinery test report for an automated chicken cutlet maker feasible?

Yes, businesses can solicit machinery test reports from Alibaba.com suppliers to ascertain the automated chicken cutlet maker's quality and functionality prior to purchase.

What kind of after-sales service is typically offered with an automated chicken cutlet maker purchase?

After-sales services accompanying an automated chicken cutlet maker may include online assistance, video technical support, and the availability of engineers for overseas machinery service. These offerings can vary among suppliers.

How does voltage influence the operation of an automated chicken cutlet maker?

Voltage specifications differ across machines; thus, it is crucial to ensure that the equipment is compatible with your facility's electrical infrastructure for safe and effective operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4