Introduction to China Nail Molding Machines

Nail molding machines from China are integral components in the manufacturing sector, designed to produce a variety of nails used in numerous industries. These machines are engineered to cater to the high demands of modern production lines, ensuring efficiency and reliability in nail production.

Types and Applications

The china nail molding machine category encompasses a diverse range of models, each tailored for specific types of nails and production volumes. From coil nail machines to strip nail machines, the selection is vast, with each type serving distinct sectors such as construction, carpentry, and furniture making.

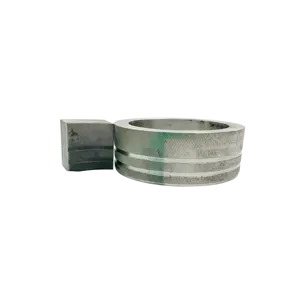

Features and Materials

A nail making machine typically boasts features that enhance productivity, such as automated feeding systems and speed control. The robust construction of these machines often involves high-grade materials like carbon steel and alloys, which contribute to their durability and long service life.

Advantages of Utilizing Advanced Machinery

Incorporating a nail production machine into your operations can significantly boost efficiency. These machines are designed with precision engineering to minimize waste and maximize output, providing a swift return on investment. The adaptability of a nail manufacturing machine allows for the production of nails in various sizes and specifications, meeting diverse market needs.

Operational Considerations

When integrating a nail machine into your workflow, operational aspects such as ease of use, maintenance requirements, and energy consumption are crucial. Machines from China are often designed with user-friendly interfaces, making them accessible to operators with varying levels of expertise.

Selecting the Right Machine for Your Business

Choosing the appropriate china nail molding machine involves assessing production capacity, space availability, and specific manufacturing needs. It's essential to select a machine that aligns with your production goals and can be seamlessly incorporated into your existing setup.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4