Introduction to China Polishing Pads

Polishing pads are essential tools in surface finishing industries, and China polishing pad varieties stand out in the global market for their diversity and adaptability. These pads are crafted to cater to a multitude of polishing needs, from automotive detailing to fine furniture finishing. The category encompasses a range of materials, each designed to offer specific benefits during the polishing process.

Types and Materials

The selection of polishing pads from China includes foam, microfiber, and wool options. Foam pads are known for their large cells, which can retain significant amounts of paint or contaminants, facilitating a smoother polishing action. Microfiber pads, with their dense fibers, provide increased friction and are adept at handling tougher polishing jobs. Wool pads, characterized by their coarse texture, deliver an aggressive cut and are typically used for more intensive polishing tasks.

Features and Applications

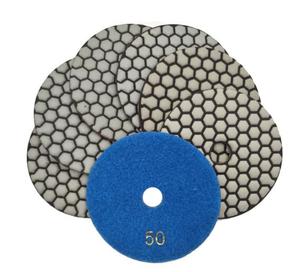

Each polishing pad type is designed with specific features to address different surface conditions and desired finishes. Foam pads vary in cell size and wall thickness, affecting their stiffness and absorption capabilities. Microfiber pads leverage the strength of their fibers for a balance of cut and finish, while wool pads offer a robust solution for removing deeper imperfections. These variations ensure that there is a suitable China polishing pad for every application, from automotive to marine, and beyond.

Advantages of Foam Polishing Pads

Foam polishing pads are particularly popular due to their versatility. They come in various shapes and sizes, accommodating a wide range of polishing machines and techniques. The ability of these pads to hold and distribute polishing agents evenly results in a consistent and controlled finish, making them a go-to choice for professionals seeking precision.

Understanding Microfiber and Wool Pads

Microfiber pads are distinguished by their ability to offer a balance between absorption and abrasiveness, making them ideal for both cutting and finishing steps. Wool pads, with their natural fibers, provide a level of aggression suitable for addressing more significant surface imperfections, often used in the initial stages of polishing.

Choosing the Right Polishing Pad

Selecting the correct polishing pad is crucial for achieving the desired outcome. Factors such as the hardness of the pad, the type of polish being used, and the condition of the surface all play a role in this decision. It is important to match the pad to the task at hand to ensure optimal results without causing damage to the surface being polished.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4