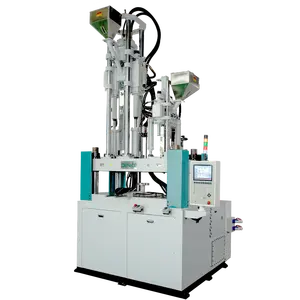

Introduction to CIF Injection Moulding Machines

Injection moulding technology has revolutionized the manufacturing industry, and cif injection moulding machines stand at the forefront of this innovation. These machines are pivotal in shaping plastic materials into a wide array of products, catering to various sectors such as consumer electronics, pharmaceuticals, food and beverage, and the automotive industry.

Design and Functionality

The design of cif injection moulding machines is focused on durability and efficiency. A single-cylinder system equipped with a servo-valve ensures a consistent and rapid response during operation, reducing the likelihood of defects. The special screw design enhances plasticizing capabilities, allowing for increased shot weight and speed, crucial for high-demand production environments.

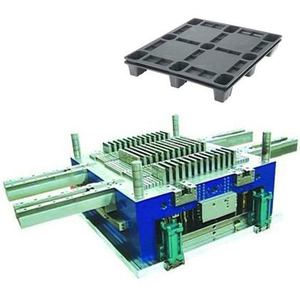

Applications and Versatility

The versatility of cif injection moulding equipment is evident in its wide range of applications. From creating thin-wall containers for the packaging industry to intricate PVC pipe fittings, these machines are capable of handling diverse molding tasks. The adjustable clamping force, which ranges significantly, allows for precise resistance to external machining forces, ensuring the production of components that meet exact specifications.

Material and Construction

In the construction of these machines, attention to detail is paramount. The steel bush in the clamping unit is designed to minimize wear resistance, which in turn reduces the need for lubrication oil, leading to cost savings in maintenance. This thoughtful engineering ensures that the plastic injection moulding machine not only meets industry standards but also operates with improved accuracy and longevity.

Advantages of Using CIF Injection Moulding Machines

Investing in a cif injection moulding machine means committing to a product that is designed for longevity and precise operation. The machines' ability to resist wear and maintain high performance with less maintenance is a testament to their advanced design. Furthermore, the specialized nature of these machines allows for customization to meet the specific needs of various preform sizes, enhancing their utility in a production setting.

Choosing the Right Machine

Selecting the right injection moulding machine is crucial for any plastic processing business. With the vast array of options available on Alibaba, businesses can find the machine that precisely meets their operational requirements and production goals. The platform's extensive listing of wholesale cif injection moulding machines ensures that every business can find the equipment that aligns with their specific molding needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4