(27642 products available)

Cold bending equipment is a type of industrial machinery used to bend metal materials at room temperature.

Roll forming machine

Roll forming machines are widely used types of cold bending equipment. They are used to continuously feed and bend metal strips into products with cross-sectional shapes. Their good adaptability allows for mass production with low material waste. Besides, Roll forming machines are suitable for high-precision and rapid production of various asymmetric profiles.

Angle steel bending machine

Angle steel bending machines specialize in bending angle steel. They can directly bend the angle steel according to the required shapes and are widely used in construction, sign making, and other industries. Based on the control system, they can be divided into CNC, PLC, and manual control. Moreover, the machine also has different kinds of modules and shapes.

Box Section Bending Machine

This kind of machine is used to achieve complex bends in heavier gauge steel. For instance, the Roto-Box machine uses a single-axis planetary rotation to bend square or rectangular tube. Usually, they can bend sections to any angle with high precision and without damaging the material.

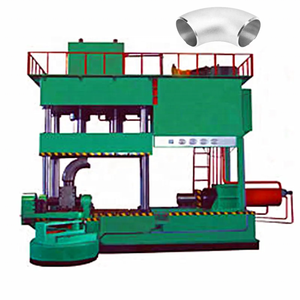

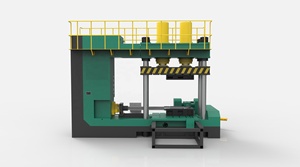

Hydraulic bending machine

Hydraulic bending machines utilize hydraulic systems to generate bending forces. They are suitable for bending thick plates and bars. Moreover, they have high-automation and efficiency.

The following specifies the typical specifications of a cold bending machine for metal and highlights their maintenance requirements.

Due to the complex structure of cold bending equipment, there are no prescribed maintenance methods for them. Instead, the maintenance methods depend on the specific models and types. However, the following general maintenance suggestions are applicable to all cold bending equipment.

Cold forming equipment has many applications in industries because it is cost-effective and efficient for shaping various metals used for structural supports and parts. Here are some applications of cold bending machines.

Construction industry

Architects and builders use cold bending machines to make hollow structural sections and purlins. These HSCs support large building frameworks, while purlins serve as horizontal beams in roof structures. Purlins transfer structural loads to frames or walls. HSCs and purlins are created from cold bending metal, which improves strength without additional costs or material.

Automotive industry

The automotive industry heavily relies on cold bending machines. Car manufacturers use these machines to make strong chassis, body parts, frames, window frames, and bumpers. All of them must be strong but also lightweight, so as not to add unnecessary weight to the vehicle. Using the cold bending process improves the strength-to-weight ratio of all parts while maintaining low costs.

Furniture industry

The home and office furniture industries create many products like tables, office workstations, racks, cabinets, shelf supports, clothes drying racks, and bed frames using cold bending equipment. Besides making furniture pieces more durable, cold bending improves the stability and bearing capacity of support structures.

Electrical enclosures

This industry uses cold benders to make electrical enclosures from cold-rolled materials like mild steel, aluminum, and stainless steel. These materials are strong, long-lasting, and corrosion-resistant, making them durable. Additionally, they offer protection against external elements and unauthorized tampering with the equipment inside.

Signs and displays

The signage and displays industry creates structures using cold-bent alloy and stainless steel. Neon signboards, billboards, and digital screens use cold bending metal for its aesthetic appeal and durability. This metal can make elaborate designs with excellent precision while offering strength and support to the structure.

Solar panels

Cold bending machines create the mounting racks used to install solar panels. These racks support the solar panels and help to secure them to rooftops or the ground. Because cold bending helps make them lightweight, they will not add any unnecessary weight to the structure. Solar energy is essential to a sustainable future, and cold bending improves the strength of solar mounting racks.

When buying cold bending machinery, buyers need to consider factors such as capacity, automation and control, bending accuracy, tooling and attachments, energy efficiency and safety features. These are important because they will determine whether or not the available cold bending equipment meets the specific use needs.

Buyers should consider the maximum capacity of the available cold bending equipment. This is usually measured in terms of the maximum thickness and width of the metal it is capable of bending. The equipment's capacity should be well-matched to the thickness and width of the metals that will be used in a particular application. Also, the type and size of the project will determine the required capacity. For instance, large-scale infrastructure projects may call for high-capacity machinery, while smaller projects may require medium to low-capacity machines.

It is also important to consider the type of automation and control systems that come with a piece of cold bending equipment. Buyers should choose equipment with features that can precisely and consistently achieve the desired bends. Such equipment will have to advanced CNC controls and programmable settings. These features enable precise angle adjustments, multiple bending sequences, and automation of repeating bending tasks. If provided for, these options can also streamline production processes and improve efficiency. Essentially, the type of control and automation in the equipment will depend on the project type and the required bending accuracy.

Cold bending tools are designed to achieve various bending precisions. As such, when purchasing, buyers must choose equipment that can achieve the level of precision their project requires. Availability of required toolings and attachments is also an important factor to consider. Certain projects may demand specialized bends or shapes. In this case, buyers will need to go for cold bending equipment that has the required toolings and attachments.

The energy efficiency of a piece of cold bending equipment is important for both operating costs and environmental impact. During the operation of the machinery, energy-efficient options will reduce the equipment's energy consumption.

Finally, the cold bending equipment must have all the necessary safety features to minimize workplace hazards. This can include emergency stop buttons, safety guards, and operator training requirements. Safety standards and regulations must be complied with.

Q1: What materials are suitable for cold bending?

A1: Metal cold bending involves using certain metal types. For instance, most cold metal bend devices can use aluminum. Titanium is hard to bend, and buyers may need to get equipment specifically designed to cold bend titanium.

Q2: Can cold bending affect the strength of a metal?

A2: Yes, cold bending brings a unique atomic-level effect in metals. Cold bending can make a metal stronger because of the increased dislocation density. However, if the metal is bent further than its elastic limit, it will lose its strength.

Q3: What are the hottest cold bending methods?

A3: The cold bending method used depends on the shape required. Rolling is the most common cold bending method. Other methods are the U and V method, press brake, notching, and flanging.

Q4: Should one Purchase automated or manual cold bending equipment?

A4: Manual bending equipment is more affordable, but automated is faster, precise, and convenient.