(14529 products available)

Transformers are critical components used in electrical systems, and cooling transformers help to prevent overheating. Many types of cooling transformers are available, and each serves unique functions and requirements. The following are the most common types found on the market:

These transformers use water as the cooling medium to maintain optimal temperatures even under high loads. Found in larger industrial settings, water cooling provides efficient heat removal thanks to its high heat capacity. Often designed with cooling jackets on the transformer, water-cooling systems are ideal for situations where air cooling is either insufficient or impractical due to high temperatures, heavy currents, or confined spaces.

Natural esters are derived from vegetable oils and are used in transformers as a cooling medium. Compared to mineral oils, which are derived from petroleum, natural esters offer better environmental benefits and electrical insulation properties. They are more fire-resistant and ideal for transformers operating in high-risk environments. Many cooling transformers use natural esters due to their renewable nature and biodegradability. For their environmental benefits, they are increasingly used in transformer cooling and fire safety.

Heat sink cooling transformers dissipate heat using a heat sink, usually metallic. In situations where airflow is compromised or unreliable, heat sinks provide a reliable cooling solution. The transformer often incorporates heat sinks in compact electronic devices or high-density installations. It works by absorbing and dissipating heat through convection and radiation, maintaining a stable operating temperature.

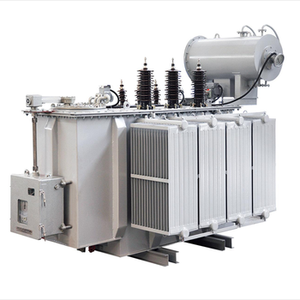

An air cooling transformer is the most common cooling type that uses fans or natural convection to cool the transformer's core and windings. Its simplicity and low maintenance needs make it the go-to choice for a variety of applications. Air cooling is adequate for lower power transformers and in settings where the availability of airflow is constant. While not as effective under heavy loads, air cooling is cost-effective and easy to install. Since air cooling is often used in smaller and more accessible areas, it is the most widely used for cooling transformers.

These transformers cool the system using steam or water generated by a boiler. They are favored in high-power applications, such as in power plants, because they integrate seamlessly with existing steam and water systems. These transformers often have heat exchangers connected to the boiler, allowing efficient heat removal. They are used in industries where high power and heat management are concerns.

Transformers are everywhere in industrial settings, and cooling transformers are especially critical in heavy-duty environments because they provide stability and safety. The following are common industrial applications where cooling transformers play a key role:

Cooling transformers are commonly found in electrical power generation stations, including coal, gas, and nuclear power stations. These high-power transformers will need effective cooling to manage heat levels and ensure efficiency. Water-cooled transformers are often used because they can handle the large amounts of heat generated and are integrated into the station's cooling system.

In high-voltage substations, transformers step up and step down voltages for transmission and distribution. These large transformers generate a lot of heat, and cooling systems maintain their optimal temperature ranges. Air-cooled transformers are common in substations because they are easy to install and provide sufficient cooling for moderate surfaces.

In large industrial manufacturing plants, cooling transformers are integrated into production machinery and equipment. These transformers power tools, machines, and other equipment while maintaining a stable temperature. Fluid- or air-cooled transformers are commonly used, depending on the equipment's space constraints and power requirements.

The mining industry relies on heavy machinery, and cooling transformers are used to power this equipment. These transformers are often exposed to harsh environments and must be able to withstand dust, heat, and moisture. Mining operations often use oil-immersed or water-cooled transformers, which are more durable and have better heat dissipation.

Petrochemical and chemical plants use large electrical systems, and cooling transformers keep this equipment operating safely and efficiently. These transformers are found in reactors, separators, and other process equipment. Since safety is always a concern with volatile chemicals, fire-retardant transformer oils are often used in these environments.

The following are product specifications and features of cooling transformers:

The right cooling transformer must effectively manage heat and keep the system running optimally. The following factors should be considered when selecting a cooling transformer:

The load capacity should be one of the most important factors to consider. A transformer should be able to handle its anticipated electrical load without becoming overheated. An underloaded transformer may still require cooling, but it will not need it as much as a heavily loaded one. On the other hand, overloading a cooling transformer can result in overheating and even failure. Request the supplier for cooling transformers that match the required loads of the intended applications.

The environment where the transformer will be installed will affect its cooling needs. Factors like temperature, humidity, and altitude can all affect cooling transformer performance. High temperatures can increase the cooling requirements, while humidity can affect cooling mediums like air. Ensure the transformer is designed to operate effectively in the specific conditions they will be subjected to.

Maintenance needs vary depending on the type of cooling system used. Air-cooled transformers require little, if any, maintenance beyond periodic inspections. Water- or oil-cooled transformers need regular checks for leaks, contamination, and possible chemical reactions between the water and transformer materials. Heat sink transformers, on the other hand, require more frequent cleaning to prevent heat sink obstruction. Consider transformers with maintenance needs that can fit within operational schedules.

Cooling transformers vary in size and complexity, with some having integrated heat exchangers and others with external cooling components. Larger, more complex, water cools, or boiler coolants, may require more space and installation expertise. In contrast, air-cooled or heat sink transformers are simpler and often more portable. The size of the transformer should be proportionate to the space available for its installation. It is also important to consider how the cooling system will integrate with existing infrastructure.

The primary job of a transformer is to provide electrical isolation and voltage adjustment. However, they also generate heat during operation, and a cooling transformer will help dissipate that heat to keep it at an optimal temperature. Consider the cooling needs of the transformer. Forced-air cooling can provide higher cooling rates, while natural convection relies on ambient air with lower cooling capacity. Water-cooled transformers have higher cooling capacity than air-cooled ones.

A1. Yes, many cooling transformers are designed to withstand outdoor conditions. These often have protective enclosures that shield them from the elements. Outdoor installations must also consider factors like temperature extremes, humidity, and exposure to dirt and debris. The Transformers must be rated for outdoor use, and their cooling systems should be suitable for the climate where they will be installed. For instance, air-cooled transformers may require additional protection from moisture and dust in outdoor settings.

A2. The oil in cooling transformers like oil-immersed transformers serves two primary functions. One is cooling, while the other is electrical insulation. Transformer oil transfers heat away from the core and windings, keeping the system at a stable temperature. It also insulates electrical components to prevent short circuits. Cooling mediums like esters and water offer eco-friendly alternatives with similar or better insulating properties.

A3. High humidity levels can impact the cooling process by affecting the air's density and, therefore, its cooling capacity. This can especially affect air-cooled transformers since they rely on airflow for cooling. In extremely humid conditions, air may have to be denser to provide an adequate flow, which, in turn, reduces its cooling capacity. This may require manufacturers to increase the cooling air condition frequency in high humidity areas.

A4. Certain signs that indicate a cooling transformer needs maintenance include strange noises, irregular temperature patterns, or visual leaks of the cooling material. Excessive heat or fluctuations in temperature can indicate that the transformer is either overloaded or the cooling system has failed. Cracks, discoloration, or visible wear and tear on the transformer or its components are good indicators that maintenance is required.

A5. Cooling transformers are suitable for renewable energy systems like wind and solar power. In solar power plants, for instance, cooling transformers maintain the stability of power outputs, especially in large-scale concentrated solar power systems. Similarly, cooling transformers in wind farms help manage the electrical system's voltage and frequency, especially in large offshore wind farms.