Popular in your industry

Related Searches:

Top categories

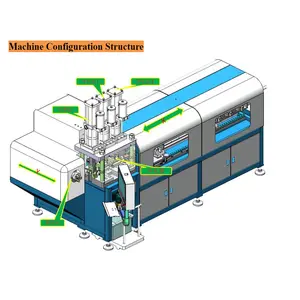

About copper busbar bending machine

Introduction to Copper Busbar Bending Machines

Copper busbar bending machines are essential tools in the electrical industry, designed for shaping copper bars into various angles and configurations. These machines streamline the process of manipulating copper busbars, which are crucial components in electrical conduction and distribution systems. With precision engineering, these machines cater to a range of bending tasks, ensuring that each bend meets the exact requirements for electrical projects.

Types and Applications

The versatility of copper busbar bending equipment is evident in the variety of types available. From manual to fully automated systems, these machines serve different operational needs. The applications are broad, ranging from small-scale electrical panel builders to large industrial settings where the bending of heavy-duty copper bars is a regular task. The adaptability of these machines makes them suitable for intricate designs requiring precise angles and complex shapes.

Features and Materials

A copper busbar machine is typically constructed from materials that resist corrosion and wear, such as industrial-grade steel. This ensures longevity and consistent performance. Features like linear guides and high precision ball screws are integral to the machine's functionality, providing smooth operation and exact bends. The incorporation of hydraulic systems in some models allows for the effortless shaping of even the most robust copper bars.

Operational Advantages

The operational benefits of a copper busbar bender are numerous. These machines are designed for ease of use, often requiring minimal training to operate. The integration of functions such as punching, shearing, and bending into a single machine enhances efficiency, reducing the need for multiple pieces of equipment. This multifunctionality is a significant advantage for settings where space and time are at a premium.

Maintenance and Durability

Maintenance of a copper busbar bending machine is simplified through design features such as spring system connections, which reduce the need for frequent hardware tightening. The use of retardant materials in construction not only extends the machine's lifespan by preventing rust but also ensures that the machine can withstand the rigors of a high-production environment.

Choosing the Right Machine

Selecting the appropriate copper busbar bending equipment involves considering the specific requirements of the task at hand. Alibaba.com hosts a range of machines, differing in size, shape, and color, each designed to meet various operational demands. While browsing the platform, buyers can compare the features of different models to find a machine that aligns with their production needs.