Introduction to Electroplating Machines

Electroplating machines are pivotal in the process of coating a metal object with a thin layer of another metal by means of electro-deposition. The significance of this technology spans across various industries, from jewelry to automotive manufacturing, offering both aesthetic and functional benefits to treated products.

Types and Applications

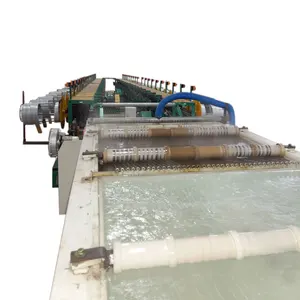

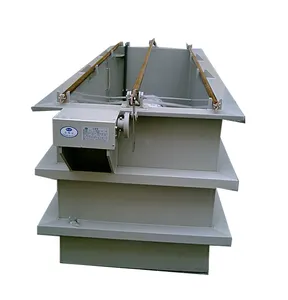

The diversity of electroplating machines is evident in their applications. For instance, a gold plating machine is often utilized in the jewelry sector to enhance the appearance and wearability of pieces. In contrast, a zinc plating machine is typically employed for its corrosion-resistant properties, making it a staple in hardware and automotive industries. Barrel plating machines and small electroplating machines cater to different scales of operation, with the former suitable for bulk processing and the latter for more intricate or delicate tasks.

Features and Materials

Modern electro plating equipment is designed to accommodate a range of metals, including gold, silver, copper, and nickel. The machines come with various features to ensure efficiency and precision. For example, a silver plating machine might boast advanced controls for thickness and deposition rate, while a copper plating machine could be designed for durability and consistent performance under high throughput demands.

Advantages of Electroplating

Electroplating offers numerous advantages, such as increased durability, enhanced electrical conductivity, and improved resistance to corrosion and wear. Moreover, electroplating can provide a desirable finish to items like jewelry, where a gold plating machine for jewelry can impart a luxurious sheen to the final product. The process also allows for material savings by using expensive metals economically, only where needed for functionality or aesthetics.

Choosing the Right Machine

Selecting the appropriate plating equipment is crucial for achieving desired results. Factors to consider include the size of the items to be plated, the type of metal used for plating, and the expected production volume. A jewellery plating machine might be ideal for boutique operations, while industrial-scale ventures may require robust systems capable of handling larger items with higher efficiency.

Conclusion

In conclusion, Alibaba.com serves as a comprehensive marketplace for sourcing various types of metal plating machines. Whether the need is for a machine capable of delicate jewelry work or for large-scale industrial applications, the platform connects buyers with a spectrum of reliable suppliers to meet their specific electroplating needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4