(200508 products available)

An extruder is a device used to create objects of a fixed cross-sectional profile, such as aluminum extrusions, by pushing or drawing material through a die. This process is prevalent in industries where continuous production of a specific shape or form is required. The alu extrusion process is commonly used to manufacture a variety of products, ranging from simple household items to complex industrial components. An extruder may be used with a variety of materials, including metals, plastics, and food products. The versatility of extruders makes them crucial in the manufacturing sector for their ability to produce consistent and high-quality products in a cost-effective manner.

Extruders are used in various industries, including the food and pharmaceutical industries. In the food industry, extruders are used to produce breakfast cereals, snacks, pasta, and pet food. The pharmaceutical industry employs extruders to manufacture drug dosage forms and medical devices. Plastic extruders are used in the production of pipes, tubes, and profiles for construction and industrial applications. Moreover, extruders are utilized in the automotive industry to manufacture components such as weather stripping and trim. In the aerospace sector, extruders are used to create structural components. In the realm of renewable energy, extruders play a vital role in manufacturing components for solar panels and wind turbines. The extruder's versatility makes it an indispensable tool across various industries, contributing to the efficient and cost-effective production of a wide array of products.

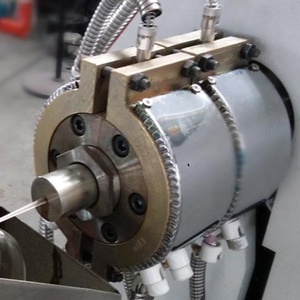

There are several common types of extruders, each designed to meet specific manufacturing requirements. Single-screw extruders are the most basic type, featuring a single rotating screw within a barrel. Twin-screw extruders, with either co-rotating or counter-rotating screws, offer enhanced mixing capabilities and are suitable for a range of materials, including polymers and food products. Aluminum extruders are specially designed for the extrusion of aluminum profiles and are equipped with features to handle the unique properties of aluminum. Similarly, plastic extruders are tailored for the extrusion of plastic materials, with variations such as single-screw, twin-screw, and multi-screw extruders.

Moreover, hot melt extruders, also known as melt pumps, are used for precise control of temperature-sensitive materials. These extruders are vital in the pharmaceutical and adhesive industries. Finally, ram extruders are a specialized type that uses a hydraulic or mechanical ram to extrude materials. These are used in applications where high-pressure extrusion is required, such as in the production of ceramics and some food products.

The primary advantages of using an extruder in manufacturing processes include its ability to ensure consistency in the production of complex shapes and profiles. Extruders are highly efficient, capable of continuous production and minimal material wastage. They offer versatility, allowing for the extrusion of a wide range of materials and the creation of customized profiles. Furthermore, extrusion is a cost-effective process, contributing to the economic viability of manufacturing operations. The advantages of extrusion, along with the diverse types of extruders available, make them indispensable across various industries, driving innovation and efficient production.