Popular in your industry

Related Searches:

Top categories

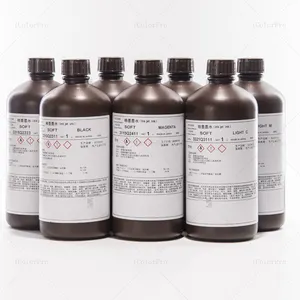

About flexo ink

Understanding Flexo Ink

Flexographic printing, commonly referred to as flexo, is a method that has revolutionized the printing industry, largely due to the versatility and consistency of flexo ink. This specialized ink is designed for use in the flexographic printing process, which is known for its ability to print on a wide variety of substrates.

Types of Flexo Inks

The flexographic industry utilizes various ink types to cater to different printing needs. Solvent-based and water-based inks are the most prevalent, each with unique properties that determine their suitability for specific applications. Solvent-based inks are known for their quick-drying capabilities and durability, making them ideal for packaging materials that require resistance to external elements. Water-based inks, on the other hand, are an eco-friendlier option, often used for food packaging due to their lower toxicity levels.

Applications of Flexo Printing Inks

Flexo printing inks are incredibly versatile, used in various applications from food packaging to high-quality business materials. Their adaptability allows them to be used on non-porous substrates, which is essential for certain types of packaging. Moreover, the advancement in UV-curable flexo inks has expanded their use to more complex and high-end printing tasks, offering quick-drying solutions and durability.

Features and Advantages

The features of flexo printing ink contribute to its advantages. These inks are known for their vibrant colors and ability to maintain integrity on different textures, which is crucial for brand consistency across various materials. Additionally, the fast-drying nature of certain flexo inks increases production speed, thereby enhancing efficiency in printing operations.

Materials and Composition

The composition of flexo inks varies based on their type. For instance, UV-curable inks contain photoinitiators that respond to UV light, while solvent-based inks incorporate organic solvents to facilitate drying. The choice of materials in ink formulation is critical, as it affects the adhesion, finish, and durability of the print.

Selecting the Right Flexo Ink

Selecting the appropriate flexo ink requires consideration of the printing substrate, desired finish, and environmental factors. It is essential to match the ink type with the printer's capabilities and the project's requirements to achieve optimal results. While navigating through the selection process, one must consider the ink's compatibility with the substrate and the intended use of the printed material.