Popular in your industry

Related Searches:

Top categories

About hot runner controller price

What is Hot Runner Controller Features And Pricing

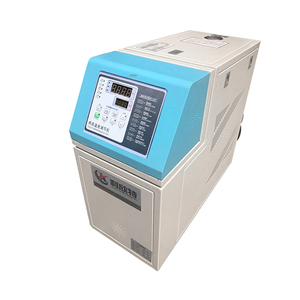

A hot runner controller is an essential component in the field of plastic injection molding, acting as the brain that governs the operation of a hot runner system. These controllers are sophisticated devices designed to manage the temperature and often the sequence of operations within a hot runner system, ensuring precise control over the plastic melt as it is injected into the mold. They are ideal for manufacturers who require consistent and high-quality plastic parts, as well as for applications where traditional runners would result in excessive material waste and longer cycle times.

The principle behind a hot runner controller is based on creating a controlled environment for the plastic melt. It typically consists of a combination of heating elements, sensors, and software that work in unison to regulate the flow of plastic material into the mold. The controller's heating elements are often made from materials such as resistance wire or cartridge heaters, which are used to heat the plastic to a specific temperature. Sensors monitor the temperature at various points within the hot runner to ensure that the melt remains consistent. The software part of the controller allows for a range of operating parameters to be programmed, such as injection speed, pressure, and dwell time, which can be adjusted based on the requirements of the part being produced.

Hot runner controllers are essential for modern injection molding operations as they contribute to reducing material waste, improving cycle times, and enhancing the overall quality of the molded products. They are designed for use by a wide range of industries, including automotive, consumer electronics, and medical device manufacturers, who require high-precision and efficiency in their production processes.

Types of Hot Runner Controller Features and Pricing

Hot runner controllers come with various features to cater to different industrial needs. Each type offers unique benefits suited to specific applications:

-

Temperature Control: This is the foundational requirement for maintaining precise temperature settings in hot runner systems. It ensures that the molten plastic flows uniformly and that the components are heated accurately.

-

Pressure Control: Hot runner controllers with pressure control features help manage the injection process by regulating the flow of material into the mold. This helps maintain consistent pressure levels for efficient molding.

-

Timer Control: Some controllers include timer features that allow users to program the opening and closing of gates at specific times. This can be used for sequential injection molding or to create time delays between mold cycles.

-

Multizone Control: Multizone controllers offer more flexibility by dividing the heating zones of a hot runner system into multiple segments which can be individually controlled. This allows for better temperature distribution and can be particularly useful for complex molds.

-

Sequential Valve Gate Control: This advanced feature allows for precise control over each nozzle in a multi-cavity mold. It ensures that each part is filled sequentially and evenly, which is critical for high-precision applications.

When selecting a hot runner controller, it's essential to consider the specific features that align with the needs of the molding project. The pricing of these controllers varies based on the complexity of the system, the number of zones, and additional functionalities.

How to choose Hot Runner Controller Features And Pricing

Selecting the right Hot Runner controller features requires careful consideration of several factors:

-

Compatibility with Existing System: It is essential to ensure that the chosen controller is compatible with the existing injection molding machinery and hot runner system.

-

Type of Control: Determine whether you need a simple on/off control or a more sophisticated PID control suitable for precise temperature regulation.

-

Number of Zones: Consider how many zones you need to control. Different types of controllers can support varying numbers of zones.

-

Display and Interface: The type of display (e.g., LED or LCD) and interface (e.g., keypad or touchscreen) should be chosen based on ease of use and specific production requirements.

-

Alarm System: An alarm system is crucial for alerting operators to any deviations in the system that could lead to defects in the molded products.

In terms of pricing, it's important to consider not just the initial cost of the controller but also its reliability and suitability for your specific production volume and product requirements.

About Hot Runner Controller Features And Pricing on Alibaba.com

Alibaba.com stands out as an indispensable marketplace for sourcing wholesale hot runner controllers from suppliers around the globe. With an extensive selection tailored for various applications, buyers can find controllers that meet specific requirements such as temperature control, sequential heating, and multiple-zone control. The platform's user-generated content aids in filtering options to match preferences and technical specifications needed for molding operations.

Buyers can trust in Alibaba.com's commitment to facilitating trade across borders with features like mobile buying convenience and multilingual communication support. Moreover, services like Trade Assurance provide peace of mind by ensuring payment security until delivery is confirmed satisfactory.

For businesses seeking specialized solutions, Alibaba.com offers a gateway to connect with suppliers who can provide customized solutions. Whether it's adapting to unique molding challenges or scaling operations for large-scale production, Alibaba.com's network of suppliers can meet these demands efficiently. With an array of options at competitive prices, Alibaba.com empowers businesses worldwide to optimize their manufacturing processes with top-notch hot runner controllers.

Common FAQs for Hot Runner Controller Features And Pricing

What is a hot runner controller and how does it work?

A hot runner controller is a device that regulates the flow of melted plastic to the cavities of a mold, ensuring that the plastic remains in a molten state and is only injected when needed, improving efficiency and precision in the molding process.

What are the key components of a hot runner controller?

The key components include a controller unit, thermocouple or sensor, heating elements, manifold, and nozzle system. The controller unit manages the system, the thermocouple or sensor monitors and adjusts the temperature, the manifold distributes the molten material, and the nozzle system shapes the plastic.

What should I look for when selecting a hot runner controller for my business?

When selecting a hot runner controller, consider the number of zones it can handle, compatibility with your mold design, ease of installation, energy efficiency, and additional features that may benefit your specific production needs.

How do I know if a hot runner controller is suitable for my industry's needs?

Assess your industry's specific requirements, such as the type of mold you use, the material you are processing, the size of your operation, and any additional functionalities you may need like multiple zones or energy-saving features.

Can I retrofit an existing mold with a new hot runner controller?

It is possible to retrofit a mold with a new hot runner controller if it is designed to fit the dimensions and specifications of your mold and if the system allows for such an upgrade.

What types of molds are best suited for hot runner systems?

Flat molds are often recommended for producing parts with uniform thickness and minimal complexity, while injection molds can handle more intricate and three-dimensional designs.

Are there controllers that work with all types of plastics?

Not all hot runner controllers are universally compatible with every type of plastic. Ensure that the specifications match your material requirements and consult with suppliers to find a controller that meets your specific needs.

How does a zone control in a hot runner system function?

A zone control maintains precise temperature management by regulating individual heating zones within the mold, ensuring that each cavity is filled evenly and preventing defects due to temperature variations.

What is the importance of a thermocouple or sensor in a hot runner controller?

A thermocouple or sensor is crucial in a hot runner controller as it directly detects the temperature in the mold, allowing for accurate control over heating and cooling cycles, which is essential for consistent part quality.

Can hot runner controllers be integrated with existing machinery?

Many hot runner controllers can be integrated with existing machinery, but it's important to verify compatibility and consider any modifications that may be necessary to adapt the system.

How do I maintain my hot runner controller?

Regular maintenance typically includes checking heating elements and thermocouples for wear or damage, ensuring the manifold and nozzle are clear of obstructions, and monitoring the system for energy-saving opportunities.

What energy requirements should I consider when choosing a hot runner controller?

Consider the power supply type (AC or DC), voltage requirements, frequency compatibility, and whether the controller is designed for energy efficiency when not all hot runner systems are created equal.