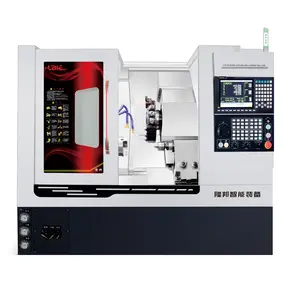

Discover the Versatility of Lathe LC400A Machines

The lathe LC400A category encompasses a range of robust and versatile machining tools designed for precision work on various materials. These lathes are a cornerstone in manufacturing environments, catering to a multitude of tasks from shaping metal to crafting intricate pieces from softer materials. The lathe LC400A machines stand out for their adaptability and are a go-to solution for businesses seeking reliable equipment for their machining needs.

Technical Specifications and Features

Each lathe LC400A is engineered to meet the demands of modern manufacturing, offering a blend of advanced features and technical specifications. These machines boast a wide array of capabilities, including variable spindle speeds, which allow for meticulous control over the machining process. With a focus on precision, these lathes come with features that ensure consistent performance, such as automated lubrication systems that minimize heat distortion and enhance machine stability.

Applications and Versatility

The application range of the lathe LC400A is extensive, demonstrating its versatility. Ideal for handling workpieces like shafts and discs, these machines are adept at operations such as drilling, reaming, and tapping. The adaptability of the lathe LC400A makes it suitable for a variety of industries, from metalworking to leather processing, highlighting its role as a multifaceted tool for professional use.

Design and Sustainability

Sustainability and design are at the forefront of the lathe LC400A series. Constructed from durable materials, these machines are built to last and withstand rigorous use. The thoughtful design extends to their operational aspects as well, with low-noise technology ensuring a more comfortable work environment. The lathe LC400A's commitment to sustainability is evident in its long service life and maintenance-friendly features.

Customization and Adaptability

Understanding that each manufacturing need is unique, the lathe LC400A machines offer various customization options. Available in semi-automatic and fully automatic versions, these lathes can be tailored to specific manufacturing requirements, ensuring that they fit seamlessly into existing production lines. The adaptability of the lathe LC400A is a testament to its design, allowing for a personalized approach to machining.

Operational Excellence

Operational excellence is a hallmark of the lathe LC400A. These machines are not only designed for ease of use but also for delivering a performance that meets the rigorous standards of modern manufacturing. With an emphasis on user-friendly interfaces and precision engineering, the lathe LC400A stands as a testament to the fusion of technology and functionality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4