Popular in your industry

Related Searches:

Top categories

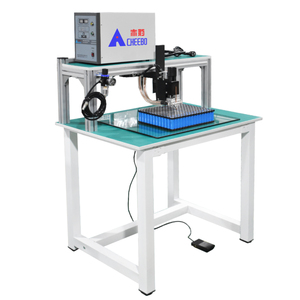

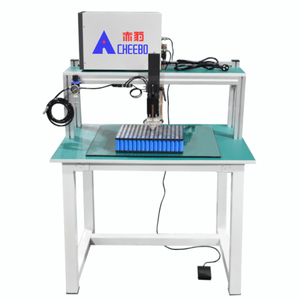

About lithium batteries welding machine

The lithium battery spot welding machine is a specialized type of equipment designed for the precise and efficient assembly of lithium-ion batteries. It plays a critical role in the production of these batteries, which are commonly used in various electronic devices, electric vehicles, and renewable energy storage systems. The machine adopts a welding technique that involves joining the components of a lithium-ion battery, such as the electrodes and current collectors, through the application of localized heat generated by an electric current. This process ensures a strong and reliable bond between the battery components, contributing to the overall performance and safety of the battery.

The types of lithium battery spot welding machine

These machines are typically categorized based on their welding mechanisms, which can include capacitive discharge welding, resistance welding, and laser welding. Each type of lithium battery spot welder has its unique advantages and is suitable for different production requirements. The capacitive discharge welding machine is known for its ability to deliver precise and rapid welding by discharging energy stored in a capacitor through the welding electrodes. The resistance welding machine, on the other hand, relies on the resistance generated at the welding interface to create the necessary heat for bonding the battery components. This type of welding is often used for its ability to produce consistent and reliable welds. Moreover, the laser welding machine employs a focused laser beam to melt and join the materials, offering high precision and minimal heat-affected zones, making it suitable for welding delicate components. The ultrasonic welding machine utilizes high-frequency ultrasonic vibrations to create frictional heat at the welding interface, enabling the bonding of materials.

The features of lithium battery spot welding machine

A spot welding machine for lithium-ion battery features a user-friendly interface and programmable settings, allowing operators to adjust welding parameters such as current, pulse duration, and electrode pressure to meet specific battery assembly requirements. In addition, the machine is equipped with advanced safety features, such as built-in monitoring systems and insulation to prevent short circuits and ensure the integrity of the battery during the welding process. It is designed to deliver consistent and repeatable welds, contributing to the overall quality and performance of lithium-ion batteries. It can handle various battery sizes and configurations, making it versatile for different production needs. The efficient cooling system is in place to maintain the optimal operating temperature during continuous use. The machine's compact and ergonomic design provides ease of integration into automated production lines or standalone operation in battery manufacturing facilities.

The application of lithium battery spot welding machine

The lithium-ion battery spot welding machine plays a crucial role in the manufacturing of lithium-ion batteries. It is widely used in industries such as consumer electronics, electric vehicles, energy storage systems, and aerospace for its ability to deliver precise and reliable welds. In the consumer electronics sector, this machine is essential for the production of batteries used in smartphones, laptops, and other portable devices. In the electric vehicle industry, the spot welding machine is utilized in the assembly of high-performance batteries for electric cars, buses, and other EVs. Energy storage systems, including solar and wind power, also rely on this equipment for the construction of robust and efficient battery packs. Furthermore, the aerospace sector employs the lithium-ion battery spot welding machine in the manufacture of lightweight and reliable batteries for spacecraft and satellites. The machine’s versatility, precision, and efficiency make it an indispensable tool in the production of lithium-ion batteries across various industries.