(1412 products available)

Magnesium oxide (MgO) ceramics are materials formed from magnesium oxide, a compound of magnesium and oxygen. It has a high melting point of about 2800 °C. This allows it to be used in a wide variety of applications. Magnesium oxide ceramics are lightweight materials with high thermal stability and conductivity. They are also chemically stable and have a high boiling point. MgO ceramics are used in industries such as electronics, aerospace, automotive, and medical.

MgO ceramics are used as substrates in electronics due to their strong, lightweight, insulating properties, and high thermal conductivity. They are also used in power electronics as heat sinks to dissipate heat from electronic components, ensuring their stability and longevity.

MgO ceramics are used in aerospace and automotive applications due to their high-temperature stability and lightweight properties. They are used in aircraft engines, exhaust systems, and brake components. Magnesium oxide is also used in the medical field to create biocompatible implants, drug delivery systems, and wound dressings.

Magnesium oxide ceramics come in different types, which include:

High melting point:

The melting point of magnesium oxide ceramics is very high, at almost 2800 degrees celsius. Because of this, MgO has to be used when making things that need to handle very hot temperatures without melting. Examples include furnace linings and kilns used for firing ceramics.

Good thermal insulator:

MgO ceramics are excellent heat insulators. This means they allow heat to pass through slowly. As a result, materials made with magnesium oxide ceramics work well for protecting against heat burns when touching hot surfaces.

Very strong and durable:

MgO ceramics do not break down easily, even in extreme heat or corrosive environments. They can last for many years without wearing out. This makes magnesium oxide ceramics reliable for industrial jobs that demand high-strength parts that won't fail quickly.

Light in weight:

Magnesium oxide ceramics are relatively lightweight compared to some other ceramic materials. This helps reduce overall weight when magnesium oxide ceramics are used in applications where every gram needs to be saved, such as in aerospace components.

Great heat resistance:

Mgo ceramics can handle very high temperatures without being damaged. They maintain their structure and strength even when exposed to intense heat for long periods. This makes them useful for applications that require materials that can withstand extreme temperatures.

Excellent electrical insulator:

They do not allow electricity to pass through easily. This makes magnesium oxide ceramics safe to use in applications where electrical conductivity could cause problems.

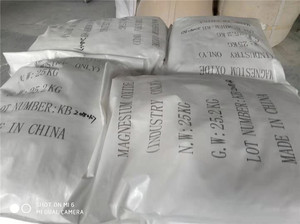

Versatile in different forms:

Mgo can be found in various forms, such as powders, bricks, and shapes that can be tailored for specific needs. This versatility allows magnesium oxide ceramics to be used across a wide range of industries and applications.

Magnesium oxide (MgO) ceramics have unique properties, making them suitable for various applications across different industries. Here are some common usage scenarios:

Refractories

MgO ceramics are used to produce refractory bricks and monolithics. These materials have high melting points and are stable in molten iron and steel, copper, glass, cement, and nonferrous metal. They are used to line furnaces, kilns, converters, and other high-temperature structures. They protect the structures from heat, corrosion, and thermal shock. They also improve energy efficiency and prevent material contamination.

Ceramics

Magnesium oxide is used to manufacture advanced technical ceramics. These include spinel, alumina, and zirconia ceramics. MgO ceramics are used in the electronics, automotive, aerospace, and biomedical industries. These ceramics have high strength, hardness, wear resistance, and thermal stability. They also have low density, high toughness, and good electrical conductivity.

Construction

MGO boards are used in the construction industry. They are used to manufacture fire-resistant boards and panels. These boards are used as interior wall, ceiling, and flooring systems. They have a high compressive strength and low thermal conductivity. MGO boards are lightweight and have excellent fire resistance. They are also moisture-resistant and have a long lifespan. They are easy to work with and eco-friendly.

Electronics

MgO ceramics are used to manufacture capacitors, insulators, and varistors. They have a high dielectric constant, low dielectric loss, and high resistivity. They are also used in cathode ray tubes and plasma display panels. Magnesium oxide acts as a phosphor coating and electron emitter. It also helps improve the brightness and efficiency of the displays.

Biomedical

Mgo ceramics are used in biomedical applications such as bone grafts, dental implants, and drug delivery systems. They promote bone formation and have good biocompatibility. MgO ceramics are used to manufacture biodegradable implants and scaffolds. They release magnesium ions in a controlled manner and enhance tissue regeneration.

Aerospace

Mgo ceramics are used to manufacture spacecraft, satellites, and aircraft components. They have a high specific strength and stiffness. MgO ceramics are lightweight and have high-temperature resistance. They are also used to produce thermal barrier coatings. These coatings protect components from extreme temperatures and reduce weight.

When choosing magnesium oxide ceramics, it is essential to consider several factors to ensure the selected product meets the specific needs and applications. Here are some of the things to consider:

Q1. What is the difference between MGO and MgO?

A1. The terms MGO and MgO are used interchangeably. However, MGO is the magnesium oxide powder's chemical formula, while MgO is its chemical name.

Q2. What are magnesium oxide ceramics used for?

A2. Magnesium oxide ceramics have different applications, including:

Q3. How are magnesium oxide ceramics produced?

A3. Magnesium oxide ceramics are produced through a process called sintering. First, magnesium oxide powder is compacted into a desired shape. Then, it is heat-treated at a temperature that is below its melting point. This process causes the particles of magnesium oxide to bond together, forming a solid piece of magnesium oxide ceramic.