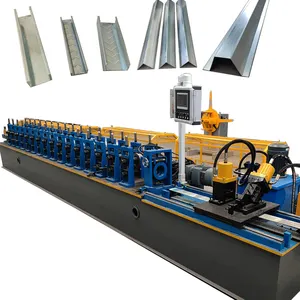

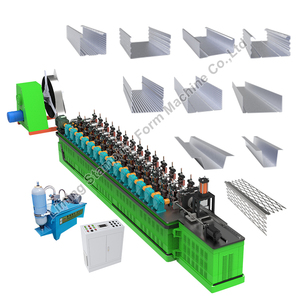

Introduction to Mini Roll Forming Machines

Mini roll forming machines are integral components in the fabrication of metal sheets into specific profiles. These compact units are engineered to transform a metal strip through a series of rollers, culminating in a finished cross-section that is utilized across various industries. The versatility of these machines allows for the production of a wide array of profiles, from roofing components to intricate frame pieces.

Types and Applications

The applications of mini roll forming equipment are diverse, ranging from construction to automotive sectors. These machines are adept at creating precise and uniform parts, such as metal roofing panels, wall cladding, and even custom trim profiles. The adaptability of these machines means they can handle various materials, including steel, aluminum, and copper, making them a staple in metalworking shops.

Features and Materials

A mini sheet metal roller is designed with efficiency and space-saving in mind, without compromising on the robustness required for metal forming processes. Constructed from high-grade materials, these machines are built to withstand the rigors of metal shaping. Advanced models come equipped with features such as programmable logic controllers (PLC) and hydraulic cutting systems, enhancing precision and automation.

Advantages of Compact Roll Forming Machinery

The compact nature of a mini roll forming machine offers several advantages. Its smaller footprint makes it ideal for workshops with limited space. Despite their size, these machines do not sacrifice performance, delivering consistent output that is essential for maintaining production standards. Additionally, their energy efficiency and ease of operation make them a cost-effective solution for small to medium-sized enterprises.

Customization and Environmental Impact

Customization is a key feature of roll forming machinery, with suppliers offering various configurations to meet specific production needs. This flexibility ensures that businesses can produce profiles tailored to their project requirements. Moreover, the environmental impact is minimized as these machines often use recyclable materials and operate with high material efficiency, reducing waste.

Choosing the Right Machine

Selecting the appropriate mini roll forming equipment involves considering the material type, profile specifications, and production volume. Suppliers on Alibaba.com can assist in identifying the machine that aligns with your operational needs. While exploring the range of options, it is crucial to focus on the technical specifications and performance capabilities rather than brand recognition.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4