Popular in your industry

Related Searches:

Top categories

About plastic boat mould

Introduction to Plastic Boat Moulds

Plastic boat moulds are essential components in the manufacturing of a wide array of marine vessels. These moulds provide the foundational shapes and contours for various types of boats, ranging from small kayaks to larger commercial vessels. The precision and durability of a plastic boat mould are critical, as they directly impact the final product's quality and performance.

Types and Applications

The versatility of plastic boat moulds is evident in their applications. They are used to create hulls, decks, and other structural parts of boats. Depending on the end-use, moulds can be designed for single or multiple cavities, accommodating the production of several parts simultaneously. The application of these moulds spans across recreational, fishing, and commercial boating industries, highlighting their integral role in marine manufacturing.

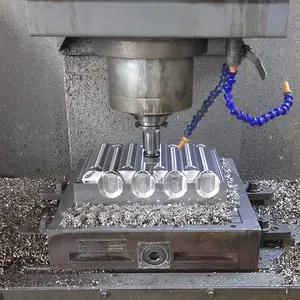

Material Selection and Features

Material selection for plastic boat moulds is a crucial decision that affects the mould's lifespan and the quality of the boat parts produced. Common materials include various grades of steel and aluminum, each offering distinct advantages in terms of durability and heat resistance. Features such as corrosion resistance and surface finish are also important considerations, as they influence the ease of part release and the amount of post-moulding work required.

Advantages of Plastic Boat Moulds

Utilizing plastic boat moulds in production brings several advantages. They are typically lighter than metal moulds, which can reduce shipping and handling costs. Their design flexibility allows for the creation of complex shapes and fine details. Moreover, plastic moulds can be more cost-effective for short production runs, providing an economical solution for custom boat designs or limited-edition models.

Optimizing Production with Mould Standardization

Streamlining production is possible by standardizing certain elements of the plastic boat mould. By harmonizing features such as lift bars, connection sizes, and clamp slots, manufacturers can achieve greater efficiency and compatibility across different moulds. This standardization can lead to reduced setup times and increased flexibility in production scheduling.

Selecting the Right Plastic Boat Mould

Choosing the appropriate plastic boat mould involves careful consideration of the design, material, and intended use. Suppliers on Alibaba.com offer a diverse range of moulds to meet specific manufacturing requirements. It is essential to communicate with suppliers to ensure that the selected mould aligns with the production goals and that any necessary customizations are understood and feasible.