(76 products available)

Market Overview: The global plastic injection molding machine market, crucial for producing items like plastic jugs, has shown robust growth. In 2024, the market size reached approximately USD 10.05 billion, following a growth from USD 9.56 billion in 2023. Projections indicate a continued upward trajectory, with an expected compound annual growth rate (CAGR) of 5.36%, potentially reaching USD 13.78 billion by 2030, according to 360iResearch™. This growth is primarily driven by increasing demand across various sectors, including consumer goods, automotive, and packaging. Notably, the injection molding segment specifically catering to plastics is witnessing significant advancements in machinery and materials, optimizing production efficiency and expanding capabilities.

Regional Insights: The Asia-Pacific region, particularly China and India, stands out as a key player in the plastic jug injection machine market, driven by a burgeoning manufacturing sector and local demand. China alone is forecasted to grow at a 6.3% CAGR, supporting the region’s dominance in the plastics industry. In contrast, the Americas, led by the U.S. and Canada, emphasize high-quality and technologically advanced solutions, influenced by consumer preferences for performance and sustainability. The European market is similarly characterized by stringent regulations and a demand for eco-friendly products, which significantly impacts purchasing behaviors. As businesses adapt to these regional trends, the emphasis on innovation and sustainability is expected to shape future market dynamics for plastic jug injection machines.

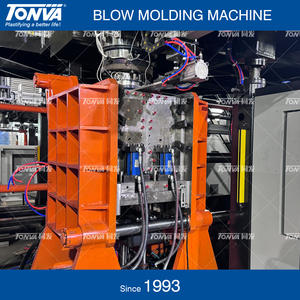

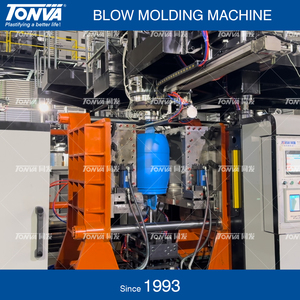

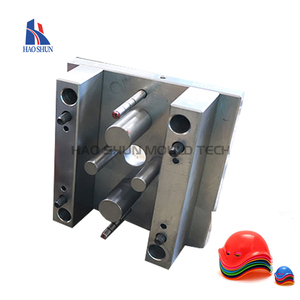

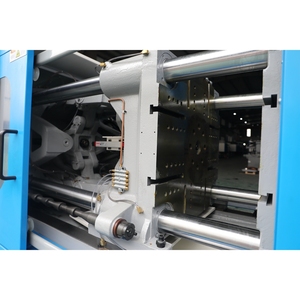

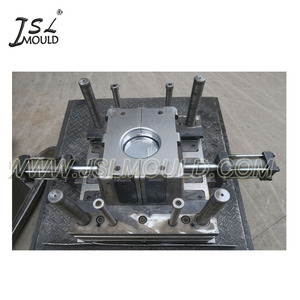

The primary function of a plastic jug injection machine is to inject molten plastic into a mold to create the desired shape. Several types of machines are available for producing plastic containers.

Vertical injection molding machine

Vertical injection molding machines are characterized by their vertical injection units and clamping mechanisms. They are ideal for producing plastic containers with complex shapes or features that require high precision and accuracy. This machine offers distinct advantages for creating high-quality plastic containers efficiently and effectively.

Multi-shot injection molding machine

The multi-shot injection molding machine works by injecting more than one material or color into a single mold to create a part with multiple colors or material combinations in one processing cycle. Plastic containers with ergonomic and functional components can be produced with this machine.

Co-injection molding machine

The co-injection molding machine, also known as multilayer injection molding, is a technique that uses two or more materials to create a part with different layers, each comprising a distinct material. This machine makes it possible to produce plastic containers with enhanced barrier properties, sustainability, and scratch resistance.

Injection stretch blow molding machine

The injection stretch blow molding machine is used to produce plastic containers with good transparency and high-strength lightweight containers, such as PET bottles. This machine offers distinct advantages for creating high-quality, lightweight, and environmentally friendly plastic containers efficiently and sustainably. It is popular in the beverage, food, and personal care industries.

Chain plate injection molding machine

This machine uses a chain plate to transport the molded parts through the cooling area. It is suitable for producing large quantities of thin-walled plastic containers at high speeds. The chain plate injection molding machine is an efficient and cost-effective solution for high-volume production of thin-walled plastic containers.

Some key specifications of plastic jug injection machines are as follows.

Plastic jug machines are widely used in various industries to produce plastic jugs for different applications. The following are some of the common applications of plastic jugs:

Food packaging companies

These companies use plastic jug injection machines to create plastic containers that are used to package various food items like sauces, syrups, juices, dairy products, and snacks. Plastic jugs are popular in the food industry because they are lightweight, easily resealable, and can be produced in food-safe materials.

Liquid manufacturing companies

These companies produce liquids such as cleaning products, chemicals, automotive fluids, and personal care products. Plastic jugs are commonly used as containers for these liquids because they are durable, leak-proof, and can be produced with child-resistant or tamper-proof qualities.

Retail stores

Retail stores, including supermarkets, convenience stores, and e-commerce platforms, sell plastic jugs as individual products or part of bundled packages. Retail stores offer plastic jugs to customers as containers for homemade beverages, cleaning solutions, storage, or other personal applications.

Non-profit organizations and charities

These organizations might be involved in fundraising, awareness campaigns, or community support initiatives. Non-profit organizations and charities may use plastic jugs to collect donations, raise funds through charitable events, or support specific causes by selling branded containers.

Selecting the right plastic jug injection machine may seem daunting, but business buyers can find their ideal models by researching the following factors.

Production capacity

Business buyers will need to define their project requirements and consider the production capacity they need. They will need to consider factors like the number of shifts per day, the length of each shift, and the days of operation per week to determine the ideal production capacity in terms of volume.

Jugs to be produced

Business buyers will need to consider the design and specifications of the jugs they intend to produce, including the material, size, weight, and complexity. They will have to ensure that the machines they choose can manufacture the intended product with the required precision and efficiency.

Machine specs

Buyers need to find out about important machine specifications like clamping force, injection volume, and flexibility. They need to ensure that the machine's performance aligns with their intended production needs.

Budget

Business buyers will consider their investment limit and the budget they have for the purchase. It's important to balance the machine's features and capabilities against the budget to find a cost-effective solution that meets business needs.

Q1. What material is used to make plastic jugs?

A1. According to a study published in Europe PMC, the most common materials for plastic jugs are high-density polyethylene (HDPE) and polypropylene (PP) because they are lightweight, durable, and resistant to chemicals.

Q2. What is the lifespan of a plastic jug?

A2. Plastic jugs, like milk jugs, can last for about 5 to 7 years when stored in a cool, dark place away from direct sunlight, but they arenot biodegradable. However, they can be recycled multiple times.

Q3. Can plastic jugs be recycled after use?

A3. Yes, plastic jugs are recyclable. Many recycling centers accept plastic jugs. After being recycled, they are often used to make new plastic products, such as containers, bottles, and piping.

Q4. How many plastic jugs does one injection machine produce in an hour?

A4.This depends on the injection speed of the plastic jug injection molding machine, the complexity of the jug being molded, the setup and changeover time, and the number of operators working with the machine. Generally, a single machine can produce between 600 to 6,000 plastic jugs per hour.

Q5. What types of plastic jugs are made using plastic jug injection machines?

A5. Plastic jugs with screw-on lids are commonly used in household cleaning products, small plastic jugs are used for shampoo and conditioner in hotels, and industrial jugs with emissions tested are used to contain gasoline and petroleum products.