Popular in your industry

Top categories

About power tailgate lift

In an era where efficiency and safety are paramount in logistics, the integration of power tailgate lifts into your fleet can be a game-changer. This comprehensive guide delves into the multifaceted world of power tailgate lifts, exploring their features, benefits, and the transformative impact they can have on your cargo handling operations. From the convenience of hands-free operation to the robust support for heavy-duty loads, power tailgate lifts are not just about accessibility; they're about enhancing operational workflow and safeguarding your workforce. Whether you're in the market for a lift that complements your luxury vehicle or need a heavy-duty solution for your commercial fleet, understanding the nuances of these systems is key to making an informed investment that aligns with your business objectives.

Understanding Power Tailgate Lifts

A power tailgate lift is an automated system designed to open and close a vehicle's rear door with the simple press of a button. This system supports various methods of activation, including the use of the original remote control, a button on the dashboard, a rear button, and a trunk switch. Additionally, it can be enhanced with a foot-kick sensor. Users can still manually operate the tailgate, which can be customized to stop at a desired height. The system is engineered to detect obstacles, halting the tailgate's motion to prevent accidents. An audible alarm signals when the tailgate is in operation, and the motor is designed to function quietly. The power liftgate is built to withstand diverse weather conditions, operating within a wide temperature range. It's important to note that the specific features and compatibility may vary based on the vehicle model and year.

Types of Power Tailgate Lifts Available on Alibaba.com

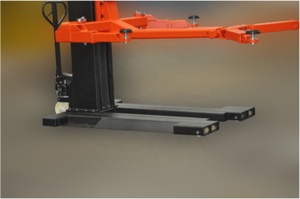

Alibaba.com offers a diverse range of power tailgate lifts suitable for various vehicle models and preferences. The selection includes electric tailgate lifts that cater to a wide array of cars, ensuring compatibility and ease of use. These lifts come in different configurations, including double pole systems for enhanced stability and single pole versions for a more compact solution.

For those seeking advanced features, there are smart electric trunk openers with hands-free operation and optional sensors that allow for gesture-controlled opening and closing. Truck owners can find hydraulic tailgate lifts designed for heavy-duty use, providing robust support for loading and unloading cargo. The platform also showcases specialized lifts, ensuring compatibility and ease of use.

Customization options are available to meet specific needs, with some power tailgate lifts offering intelligent trunk support, suitable for modern electric vehicles. For businesses looking to upgrade their fleet, there are factory OEM parts that ensure a perfect fit and seamless integration with the vehicle's existing systems. The variety extends to include electric liftgate kits that come with all the necessary components for a complete installation, making it easier for businesses to enhance their operational efficiency and safety.

Key Features of Power Tailgate Lifts

The LiftGate Series offers interior lift systems designed to facilitate cargo handling within vehicles. These systems are installed inside the vehicle, protecting them from external elements. The series includes two main models, both available with left or right-hand mounting configurations and two different lifting capacities. One model provides a lifting height suitable for full-size vans, while the other extends to a greater height, making it ideal for cube vans or box trucks. Customers can choose between a lighter capacity, which operates slightly faster, or a heavier capacity for heavier loads. Each LiftGate comes with a swing arm feature, allowing for precise positioning of loads within the vehicle, thus reducing the need for manual handling. Additionally, the LiftGates include a mounting system, DC power connection kit, and a cradle attachment for cylinders, enhancing the functionality and versatility of these lift systems.

Benefits of Integrating Power Tailgate Lifts into Your Operations

Power liftgates offer significant operational benefits by enhancing both safety and efficiency in freight handling. These systems serve as an automated solution, reducing the physical strain on workers by eliminating much of the heavy lifting associated with loading and unloading cargo. This not only minimizes the risk of injury but also streamlines the process, allowing for a more efficient use of space and time.

The convenience of power liftgates extends to their ability to function as a preventive measure against cargo spills during transit. A securely closed power liftgate acts as a barrier, potentially preventing items from sliding out unexpectedly, thus safeguarding the cargo and reducing the likelihood of loss or damage.

Moreover, the integration of power liftgates into a business's operations can indirectly contribute to more favorable insurance rates. By lowering the risk of worker injury and cargo damage, these systems can be seen as a proactive investment in safety, which insurance providers may reward with reduced premiums. The overall impact of power liftgates on a business can be substantial, offering a blend of enhanced safety measures, improved operational efficiency, and potential cost savings.

How Power Tailgate Lifts Enhance Safety and Efficiency

Power tailgate lifts offer significant enhancements to the safety and efficiency of cargo handling operations. By automating the heavy lifting process, these systems reduce the physical strain on workers, thereby minimizing the risk of injuries. The convenience of a power liftgate allows for the smooth loading and unloading of goods, which streamlines the entire process and eliminates the need for additional loading equipment. This not only saves valuable space within the cargo area but also accelerates the handling process, allowing businesses to move goods more swiftly.

Moreover, the structural design of power tailgate lifts contributes to safer transportation of goods. They serve as a preventive measure against cargo spills during transit, which can occur due to sudden stops or accidental door openings. The liftgate acts as a barrier, securing the freight even in the event of unexpected shifts, ensuring that the cargo arrives at its destination intact. This aspect of power tailgate lifts not only protects the shipment but also potentially leads to better insurance premiums due to the reduced risk of cargo loss or damage.

Selecting the Right Power Tailgate Lift for Your Business

When selecting a power tailgate lift for your business, it's crucial to consider the size of the cargo load. The capacity of the lift should align with the weight of the goods you plan to transport, ranging from lighter loads to those requiring heavy-duty support. Different types of lifts, such as tuck away lifts and rail gate lifts, offer various capacities and should be matched to your specific needs.

The compatibility of the lift gate with your vehicle is another essential factor. It's important to ensure that the dimensions of the lift gate are suitable for the width and floor measurements of your vehicle, whether it's a pickup truck, utility truck, cargo van, or another type of vehicle.

The material of the platform is also a key decision point. You'll need to choose between different materials like aluminum or steel, each with its own set of characteristics and benefits for different operational contexts.

Lastly, the energy supply for the lift gate is a consideration that can impact operational efficiency. Deciding between using your vehicle's battery or a separate battery supply will depend on the frequency and intensity of lift gate use within your business operations.

Installation and Maintenance: Maximizing the Lifespan of Your Power Tailgate Lift

Ensuring the longevity and optimal performance of power tailgate lifts involves adhering to a rigorous maintenance routine. It is crucial to follow all manufacturer maintenance recommendations, as these are tailored to the specific model and operational requirements of the liftgate. Comprehensive training for workers on the operation and limitations of the liftgate is also essential to prevent misuse and potential damage.

Proper loading techniques must be observed to maintain the integrity of the liftgate's structure and mechanics. Daily visual inspections are a proactive measure to identify and address any signs of wear or damage before they escalate into more significant issues. Collaboration with a skilled mechanic who specializes in liftgate maintenance can provide professional oversight and ensure that any technical problems are resolved promptly.

Implementing a clear process for reporting problems allows for swift action and can prevent minor issues from becoming major malfunctions. Additionally, proper storage of the liftgate when not in use protects it from environmental damage and unauthorized use, which can contribute to its deterioration. By following these guidelines, businesses can maximize the lifespan and reliability of their power tailgate lifts, ensuring that they remain a safe and efficient component of their operations.

Case Studies: Successful Implementations of Power Tailgate Lifts

A leading liftgate manufacturer required a solution for accurately counting liftgate activations to schedule maintenance effectively. Traditional counters were not up to the task, as they would often register minor adjustments as activations, leading to inaccurate counts.

To address this, a project manager and engineering team collaborated with the manufacturer to design a system that would only count activations lasting more than five seconds or involving more than two feet of travel. This approach ensured that incidental movements did not affect the count.

The solution involved a custom input PCB suitable for a range of vehicle voltages, ensuring compatibility with different models. The team selected a housing based on a pre-existing counter model and adapted it to meet the specific needs of the liftgate system.

The collaboration between the engineering teams and the customer's distribution services facilitated the development and delivery of the first batch of the tailored product within six months, demonstrating the effectiveness of custom product development in enhancing operational efficiency and accuracy.

Conclusion

Power tailgate lifts represent a significant advancement in the realm of cargo management, offering a blend of safety, efficiency, and convenience that can redefine the logistics of any business. By automating the loading and unloading process, these systems not only minimize the risk of injury and cargo damage but also streamline operations, allowing for quicker turnaround times and better space utilization. The careful selection of a power tailgate lift, considering factors like load capacity, vehicle compatibility, material, and power supply, is crucial to harnessing its full potential. Moreover, the longevity of these systems is ensured through diligent maintenance and proper usage. As evidenced by case studies, the strategic implementation of power tailgate lifts can lead to more accurate maintenance schedules and improved operational accuracy. In sum, integrating power tailgate lifts into your operations is not just an upgrade to your current capabilities—it's a strategic move towards a more efficient, safe, and cost-effective future.