(92414 products available)

Market Growth Trends: The global plastic injection molding market, which encompasses press machines for plastic, has shown impressive growth recently. According to 360iResearch™, the market surged from USD 9.67 billion in 2023 to USD 10.21 billion in 2024, and it is projected to grow at a robust CAGR of 6.32%, eventually reaching USD 14.86 billion by 2030. This growth is largely driven by the rising demand for plastic products across various industries, including automotive, consumer goods, and electronics. The Asia-Pacific region, particularly China and India, is emerging as a key player, bolstered by rapid industrialization and increasing manufacturing capabilities. In this context, press machines for plastic are pivotal for producing a wide variety of components efficiently and economically, further fueling market expansion.

Market Influencers and Challenges: Shifts in consumer behavior and industry trends are also shaping the market landscape for press machines for plastic. The demand for lightweight materials in the automotive sector and the need for precision in manufacturing are significant drivers, as highlighted by the expected growth of the automotive segment, which is projected to experience the highest CAGR from 2024 to 2030. However, challenges persist, particularly concerning the high initial costs of machinery and fluctuating raw material prices. Additionally, the increasing focus on sustainability is prompting manufacturers to adopt eco-friendly practices and materials, which could influence the design and operational capabilities of press machines for plastic. As companies navigate these dynamics, they must also consider the competitive landscape, where technological advancements and strategic collaborations play a crucial role in maintaining market relevance.

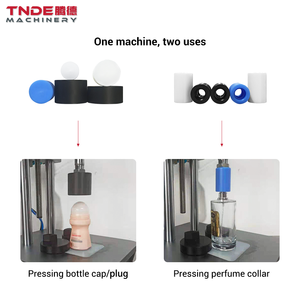

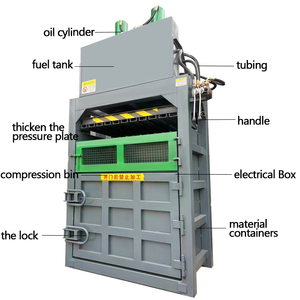

A press machine for plastic refers to a group of machines that heat and press plastic materials. It changes plastic into various shapes through methods such as extrusion, embossing, and hot stamping. The plastic press machines can be divided into types based on the operation method and the pressing surface design.

Application method

It includes the embossing press machines that apply pressure to embossed materials. Such materials can be leather, metal, or plastic. The machine can also be hot stamping ones that use heat to transfer designs onto plastics. Heat transfer may involve using dyes or foils. Another type is the plastic press molding machine, which changes the plastic into different products through molds.

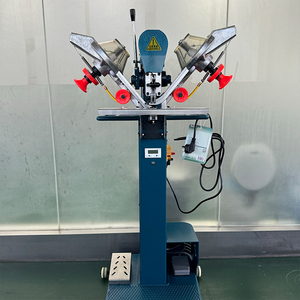

Operation method

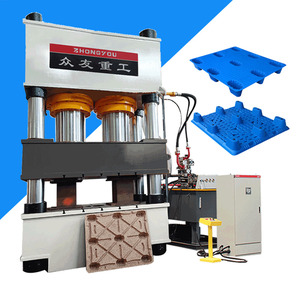

It includes hydraulic plastic press machines that use hydraulic force to apply pressure on plastic materials. The forces come from hydraulic fluids. Another type is mechanical presses that rely on electric or hydraulic motors to apply pressure through gears and pulleys.

Surface design

Flat pressing machines have flat plates that evenly press materials. The plates are heated to soften the plastic, and the material is placed and pressed between the hot plates. In contrast, the double bubble plastic press machines have two sections: the upper and lower parts. Both of them are heated. The method is efficient for large-scale productions.

These are some crucial specifications that help determine the kind of plastic press machine one would suit specific production needs.

Regular maintenance can help to identify potential issues before they escalate into costly repairs or replacements. Besides, it ensures the machine operates at its optimal capacity. Here are some maintenance tips and practices for hydraulic plastic presses and injection molding machines.

The plastic press machine has many application scenarios in various industries. Here are some of them.

Packaging industry

The Packaging industry uses a plastic compressing machine to manufacture various types of packaging. The packaging can be bottles, containers, pouches, or film. This is done by using the machine to mold molten plastic into the desired shapes. The molded plastics are then cooled and released to be used for packaging.

Automotive industry

The Automotive industry also uses plastic compression machines to produce various automotive parts. These parts include dashboards, trim components, interior parts, and body panels. The way plastic press machines are used for automotive parts is similar to other industries. The plastic is heated until it melts and is then molded into various automotive shapes. After cooling, the automotive plastic parts are used in the vehicles.

Consumer goods industry

Plastic press machines are used to produce plastic components for other consumer goods. These include toys, electronic housings, kitchenware, and sports equipment. The parts are manufactured by heating up the plastic material until it melts. After molding it into the desired shapes, they are cooled and taken out of the molds to be used.

Construction industry

In the construction industry, plastic press machines help produce plastic parts used for construction. Some of the construction parts include window frames, roofing components, and piping systems. When using the plastic press machine to make parts for construction, it is important that the materials have good durability and weather resistance.

Consider the materials:

When selecting a plastic compression molding machine, it is essential to consider the materials that the machine will be used to compress. Different machines are suited to different types of plastic, so it is important to choose one that can handle the specific material.

Determine the production volume:

The production volume is another important factor to consider when selecting a plastic press machine. These machines come in various sizes and capacities, from small desktop models to large industrial-scale machines. It is important to choose a machine that is capable of handling the desired production volume.

Think about the facility's power:

The power requirements of the plastic press machine should also be considered when making a selection. These machines can consume a significant amount of power, so it is important to ensure that the electrical system can handle the load. It may also be necessary to invest in additional power infrastructure, such as dedicated circuits or transformers, to support the machine's power needs.

Estimate the budget:

Finally, it is essential to consider the budget when selecting a plastic press machine. These machines can be expensive, so it is important to choose one that fits within the budget while still meeting production needs. It may be helpful to compare the features and prices of different machines to determine the best value for the investment.

Q1: What does a plastic press machine do?

A1: A plastic press machine shapes and forms plastics into desired parts and products by applying heat and pressure.

Q2: What are the main types of plastic press machines?

A2: The main types are the injection press machine for plastic, extrusion press machine for plastic, blow press machine for plastic, and thermoforming press machine for plastic.

Q3: What are the trends in plastic press machine technology?

A3: Trends include energy-efficient models, automation and smart technology, and multifunctional machines.

Q4: What are the advantages of using plastic press machines?

A4: Advantages include high production efficiency, energy saving, material utilization, and flexibility in processing various plastic materials.

Q5: Can a plastic press machine handle multiple materials?

A5: Some machines can process more than one type of plastic, while others are built to handle a single kind of plastic. However, it is vital to check the equipment's capabilities before using any material.