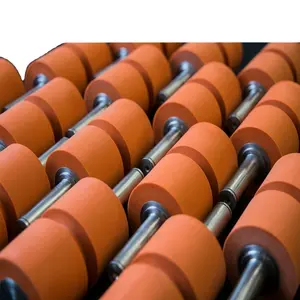

There are several advantages of using a roller machine for dipping. One of the main advantages is that this machine speeds up the production process. This helps in increasing your return on investments. It also enables you to save up on time. Another advantage of a roller machine for dipping is that it produces neat and precise rolls. When it comes to this machine, there is no room for mistakes because the operations are automated. This helps in preventing wastage. Moreover, your products will be uniform. Operating this machine is also easier. So you don’t need special skills to use it. Lastly, this machine is versatile. This means that it can be used for various applications rather than your immediate needs alone.

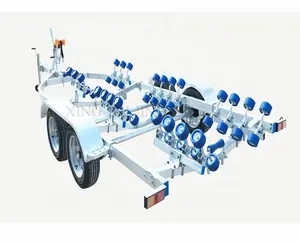

When buying a roller machine for dipping, there are various factors that you need to consider. They include the type of material, thickness, and durability. The type of material you are working on needs to be the first consideration. This is because some machines cannot handle specific types of materials with a particular length and thickness. The durability of the material also matters. Choose a machine made of steel because it is strong and durable. This ensures it serves you for long, so you don’t have to replace it.

For a wholesale roller machine for dipping,visit Alibaba.com. This online shopping platform partners with various Chinese wholesalers to offer customers a wide range of plate bending rolls. You can be sure to find one that suits your needs and budget. Visit the website at any time and place your order with a few clicks.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4