Popular in your industry

Related Searches:

Top categories

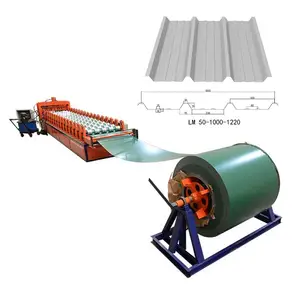

About roof tiles machine

The roof tile industry has undergone a significant transformation with advancements in technology, leading to the development of efficient machinery. The roof tile making machine is a crucial piece of equipment that automates the production of various types of roof tiles, streamlining the manufacturing process. Different types of roof tile making machines are designed to cater to specific tile styles, materials, and production capacities. This machinery plays a pivotal role in meeting the growing demand for durable and aesthetically pleasing roof tiles.

Types of Roof Tile Machines

Roof tile machines are highly versatile, capable of producing a diverse range of tiles. For instance, concrete roof tile machines are specifically engineered to manufacture robust and long-lasting tiles. These machines are designed to handle the unique characteristics of concrete, ensuring the precise formation of each tile. On the other hand, ceramic roof tile machines are tailored for the production of ceramic tiles, offering a solution for those seeking a more traditional and elegant roofing option. Metal roof tile machines are specifically designed to form metal roof tiles, incorporating advanced technologies to shape and cut metal sheets with precision. This diversity in machine types highlights the adaptability of the roof tile making process to various materials and styles, catering to the specific needs and preferences of customers.

Applications of Roof Tile Making Machines

Roof tile making machines find extensive application in the construction industry, where they are utilized to produce tiles for residential, commercial, and industrial buildings. Residential applications involve the manufacturing of tiles for individual homes, offering durability and enhancing the aesthetic appeal of the roof. Commercial buildings, including offices and retail spaces, benefit from the use of these machines to create uniform and visually appealing roofing solutions. Industrial structures, such as warehouses and factories, rely on the sturdiness and weather resistance of roof tiles produced by these machines to ensure long-term protection.

Features of Roof Tile Making Machines

Roof tile making machines are designed with several key features that contribute to their efficiency and reliability. The roof tiles machine is equipped with a robust frame that provides stability during the tile manufacturing process. The use of high-quality materials in the construction of these machines enhances their durability and longevity, allowing for continuous and consistent production. Additionally, these machines incorporate advanced control systems, often featuring user-friendly interfaces that enable operators to monitor and adjust the production parameters. This level of automation contributes to the precision and accuracy of the tile-making process. The versatility of roof tile making machines is evident in their ability to accommodate various tile sizes and designs. Some machines offer customization options, allowing for the creation of unique roofing solutions. The integration of safety features, such as emergency stop mechanisms and protective guards, ensures a secure working environment for operators. Overall, the combination of these features positions roof tile making machines as indispensable assets in the construction industry.