Popular in your industry

Related Searches:

Top categories

About sandwich panel 5 cm

What is 5 Cm Thick Sandwich Panel

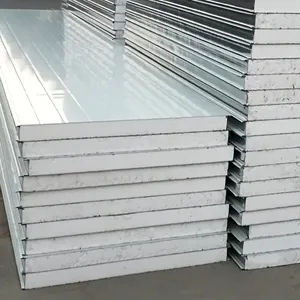

5 cm thick sandwich panels are composite material systems that consist of three layers —a core of insulating material (typically EPS, XPS, or PU foam), sandwiched between two layers of structural skin (such as OSB, plywood, or steel) on each side. The core material is what provides the insulation, while the outer layers offer strength, rigidity, and protection to the internal core. The thickness of the panels is standardized at 5 cm but can vary according to specific requirements and applications.

These panels are designed for a wide range of users, from construction professionals to DIY enthusiasts. They are suitable for applications in diverse environments such as residential buildings, commercial structures, and even agricultural farms. The manufacturing process involves bonding the core material with the exterior layers, creating a sturdy sandwich-like structure that is not only lightweight but also exhibits excellent thermal and acoustic properties.

The principle behind the 5 cm thick sandwich panel is to provide a versatile building material that is both efficient in terms of insulation and structural support. When used in construction, they can significantly reduce energy costs by maintaining interior temperatures and minimizing the need for heating or cooling systems. Additionally, the panels’ design simplifies the installation process, making them ideal for projects where time is of the essence. Their high degree of prefabrication also ensures consistency and quality that might be difficult to achieve with traditional building materials.

Types of 5 cm Thick Sandwich Panel

The market offers a variety of 5 cm thick sandwich panels tailored to meet different needs and applications. Here are some common types:

-

Polyurethane (PU) Sandwich Panel: This type is known for its excellent thermal insulation properties and is often used in the construction of cold storages and warehouses where temperature control is crucial. Its versatility also makes it a popular choice for buildings that require a high R-value for energy efficiency.

-

Rock Wool Sandwich Panel: With a core material made from mineral fiber, rock wool panels provide both good thermal and sound insulation. They are frequently used in industrial applications but can also be found in commercial and residential buildings where soundproofing is a priority.

-

EPS (Expanded Polystyrene) Sandwich Panel: EPS panels feature a core made from expanded polystyrene foam, known for its lightweight properties and good insulation. These panels are commonly used for interior applications such as basement walls and interior partitions.

-

PUR (Polyurethane) Sandwich Panel: PUR panels offer similar benefits to PU panels but with a potentially higher compressive strength. They are often used in projects that require a balance between cost-effectiveness and performance, such as in commercial refrigeration units.

How to choose 5 Cm Thick Sandwich Panel

Selecting the right 5 cm thick sandwich panel involves considering several factors that are critical for your business needs. Here are some considerations to keep in mind:

-

Application Environment: The intended location of the panel (be it for external walls, cold rooms, or office partitions) dictates the material and core material you should select. For example, if you're choosing panels for a cold room, opt for materials with high thermal resistance like rock wool or PU.

-

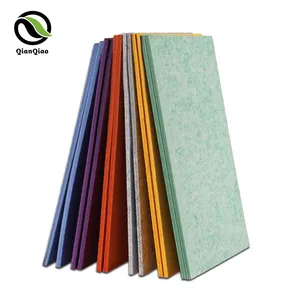

Design Requirements: The aesthetic you wish to achieve also influences your choice. Panels come in various colors and finishes that can align with your project's design style—be it modern, industrial, or traditional.

-

Load-Bearing Capacity: If your application requires structural support, opt for panels that offer high load-bearing capacity. Ensure that the chosen panel type has been tested for its ability to bear both static and dynamic loads.

-

Thermal Insulation Needs: For applications such as cold rooms, choose panels with superior insulating properties like expanded polystyrene (XPS) or polyurethane (PU) cores.

-

Durability Requirements: Consider materials that offer resistance to environmental factors such as corrosion for external walls or soundproofing qualities for partition walls.

About 5 Cm Thick Sandwich Panel on Alibaba.com

Alibaba.com stands out as a global marketplace connecting businesses with an extensive range of suppliers offering various products including 5 cm thick sandwich panels. With its vast network of suppliers, Alibaba.com provides an efficient platform where businesses can source materials that meet their specific requirements without having to negotiate with multiple vendors individually. This is particularly advantageous for projects that demand bespoke solutions catered to their unique needs.

The assurance offered by Alibaba.com's Trade Assurance service adds a layer of security by protecting payments until delivery is confirmed. This commitment to facilitating safe transactions instills confidence in buyers as they navigate through an array of options available on the site. Furthermore, Alibaba.com's user-friendly interface simplifies the sourcing process by allowing buyers to communicate with suppliers in their local language and manage orders easily through mobile devices.

By leveraging Alibaba.com's comprehensive project solution capabilities spanning graphic design to 3D model design along with cross-category consolidation services, businesses can streamline their sourcing process while ensuring they receive high-quality products that align with industry standards. Whether you're constructing a new building or upgrading an existing one, Alibaba.com offers an indispensable resource for securing the right 5 cm thick sandwich panels that will contribute to the success of your commercial project.

Common FAQs for 5 Cm Thick Sandwich Panel

What is the typical thickness of sandwich panels used in construction?

Sandwich panels come in various thicknesses, typically ranging from 30mm to 200mm, depending on the specific application and required levels of insulation and strength.

How do I choose the right type of sandwich panel for my project?

Consider the application and required features such as thermal efficiency, fire resistance, acoustics, and cost when selecting the right type of sandwich panel for your project.

Are there eco-friendly options available for sandwich panels?

Yes, there are eco-friendly sandwich panels available that use sustainable materials such as recycled content or materials that have a lower environmental impact during production and use.

Can sandwich panels be customized to specific design requirements?

Many suppliers offer customization options for sandwich panels, including various core materials, surface finishes, color choices, and design styles to fit specific project needs.

What are the benefits of using PU (polyurethane) sandwich panels?

PU sandwich panels offer high thermal resistance, excellent sound absorption, and are resistant to moisture and many chemicals, making them suitable for a wide range of applications.

How do you ensure the quality of sandwich panels when ordering from suppliers on Alibaba.com?

Alibaba.com has a network of verified suppliers who are required to meet certain standards of quality. Additionally, Trade Assurance service helps protect buyer payments until delivery is completed.

What kind of after-sale services are available for sandwich panels?

After-sale services for sandwich panels can include onsite training, installation support, and access to spare parts. It's important to discuss these services with your supplier before making a purchase decision.

How do I determine the right R-value for a sandwich panel?

The required R-value for a sandwich panel depends on the level of insulation needed. Higher R-values provide better thermal insulation, which is crucial for energy efficiency in buildings.

Are there fire-resistant options for sandwich panels?

Yes, there are fire-resistant sandwich panel options available that use materials that can withstand high temperatures or have been treated with fire-retardant chemicals, suitable for applications that require fire safety measures.

Can sandwich panels be used for both interior and exterior applications?

Yes, sandwich panels are versatile and can be used for both interior and exterior applications, providing thermal insulation and sometimes improving acoustics for interior spaces.

Is it possible to install accessories on sandwich panels after delivery?

Some suppliers may offer installation support or provide detailed instructions for the installation of accessories such as windows or doors on the panels after delivery. Always confirm with the supplier regarding any post-sale services they offer.

What core materials are available for sandwich panels?

Core materials in sandwich panels can include rock wool, glass wool, or polystyrene. The choice of core material depends on factors like thermal conductivity requirements, fire resistance, and sound absorption properties.

How do I handle transportation and unloading of sandwich panels?

Handling and unloading of sandwich panels should be done with care to avoid any damage. Follow supplier guidelines for handling and unloading to ensure that the product arrives in optimal condition.