(1174 products available)

Market Overview: The global market for screw compressors, including screw ammonia compressors, was valued at approximately $10.2 billion in 2023 and is anticipated to reach $14.4 billion by 2030, reflecting a robust CAGR of 5.0% during the forecast period. Notably, the oil-free screw compressors segment is projected to experience even higher growth, with a CAGR of 5.9%. This surge is largely driven by increasing demand for energy-efficient solutions across various industrial sectors, including manufacturing, food and beverage, and oil and gas, where reliable compressed air is essential. According to market insights, the U.S. market alone was estimated at $2.7 billion in 2023, while China is expected to grow at a remarkable 7.9% CAGR, reaching $3.1 billion by 2030.

Industry Insights: The adoption of screw ammonia compressors is influenced by a combination of technological advancements and shifting consumer preferences towards sustainability. Industries are increasingly prioritizing energy-efficient equipment that meets stringent environmental regulations. The integration of innovations such as Variable Speed Drive technology is enhancing performance and efficiency, allowing compressors to adjust based on demand. Additionally, as industrial automation gains momentum, the need for advanced screw compressors with digital controls is on the rise. Key players in the market are focusing on expanding their product offerings and enhancing service capabilities to capture emerging opportunities in niche markets. This landscape indicates a favorable environment for sustained growth as industries adapt to evolving operational demands.

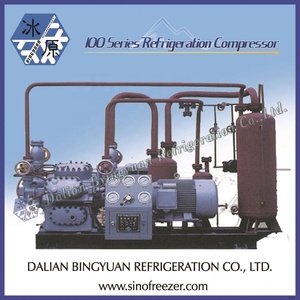

Ammonia compressors are primarily used in refrigeration systems. They come in various designs and types.

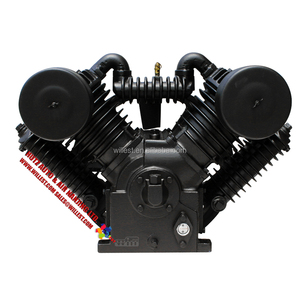

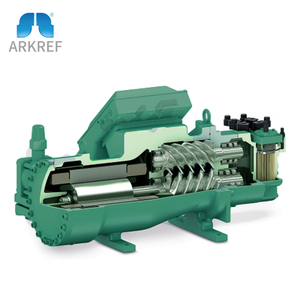

Twin Rotors:

This type of ammonia compressor consists of two rotors. One is drive-powered, while the other is idle. They intermesh to create pockets that draw in, compress, and expel the ammonia gas. Twin rotor screw ammonia compressors are very efficient when dealing with high pressures. They provide a consistent and steady compression of gas. Additionally, they have a long service life and are relatively quiet, which is good for maintaining peace in industrial settings. On the downside, this type of compressor can be large and heavy, thus taking up more space.

Double Acting Compressors:

Double acting compressors work by letting the ammonia gas flow in and get compressed from both sides of the rotor. This makes the process of compressing the gas more efficient. It could also make the compressor take up less space. However, the construction of a double acting rotor is more complicated compared to others.

Intercooled Ammonia Compressors:

An intercool ammonia compressor has two cooling stages. After the first stage, the gas is cooled down before being compressed again in the second stage. This method is good for reducing the heat produced within the compressor, thus improving its efficiency.

Single Stage Compressors:

These types of compressors use the standard method of compressing the ammonia gas in a single direction. Their design is simpler compared to two-stage compressors which are more complex. Single stage screw compressors are the most common types used in smaller industrial settings.

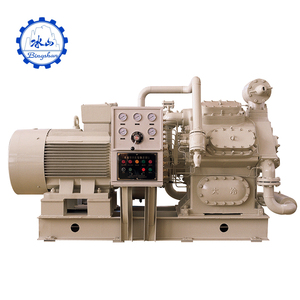

Two-stage Compressors:

Two-stage compressors compress ammonia gas in two separate chambers. They are more suitable for industries that experience high demands of pressure. Two-stage compressors offer better efficiency compared to single-stage compressors.

Air-cooled Compressors:

Air-cooled compressors use ambient air to expel out any heat which comes from the compression of ammonia gas. They have heat exchangers and condensers which facilitate cooling with the help of air. This type of compressor is more common in smaller scale industries or ones located in cold regions where water isn't easily accessible. They also cost less to install because users won’t need to set up additional water cooling systems. An air-cooled screw ammonia compressor is more environmentally friendly since it uses air, a natural resource, for cooling.

Water-cooled Compressors:

Water-cooled ammonia compressors rely on water and a condenser to disperse heat. They are more energy-efficient. It also has better cooling capacity compared to air-cooled models. A water-cooled compressor works better in large industrial settings that operate under high pressure. They are also more ideal for facilities located in hot climates. A water-cooled screw ammonia compressor can save giving facilities more cooling power to support daily operations. It also has a long service life. On the downside, water-cooled compressors use a lot of water which can raise the bills, following the expenses of water treatment to keep it clean.

Liquid screw ammonia compressors have distinct specifications depending on the specific application and producer. Here are some common specifications corresponding to what the market offers:

A well-planned maintenance schedule is crucial in extending the life of a liquid screw ammonia compressor, maintaining its efficiency, and preventing unexpected breakdowns. Below are some practical maintenance tips to support the proper functioning of the compressors:

Screw ammonia compressors are the heart of ammonia refrigeration systems. They are the backbone of the food processing industry, such as meat, dairy, pastry, beverage, chemical, and cold storage industries. This includes the following sectors:

In sum, screw ammonia compressors are specialized refrigeration machines commonly used in industrial refrigeration applications because of their ability to handle large amounts of refrigerants and high cooling capacity. They are efficient, energy-saving, and durable options for industries that need constant and reliable refrigeration. Industries that use screw ammonia compressors can benefit from their long-lasting service and excellent performance.

The following tips will help people to choose the appropriate ammonia compressor for their needs.

Q1: What are the benefits of using a screw compressor?

A1: The benefit of a rotor-stator screw compressor is continuous gas compression. They offer high efficiency, low noise levels, long service life, low wear and high durability. They are suitable for a wide range of flow rates and pressure ratios.

Q2: Are ammonia compressors liquid or vapor first?

A2: In the ammonia refrigeration compressors, the gas enters the suction header and then moves into the cylinder or shell. The refrigerant gas is compressed in the cylinder and header is discharged into the discharge header in a vapor form.

Q3: What are the types of ammonia screw compressors?

A3: There are mainly two types of ammonia compressor refrigeration: ammonia reciprocating compressor and ammonia screw compressor. The second one, the ammonia screw compressor, is the most preferred due to its higher efficiency.