Popular in your industry

Related Searches:

Top categories

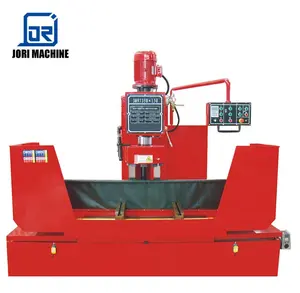

About surface grinding machine parts

Introduction to Surface Grinding Machine Parts

Surface grinding machine parts are essential components that contribute to the efficiency and precision of surface grinding operations. These parts play a crucial role in ensuring the smooth functioning of surface grinding machines, which are widely used in various industries for achieving high-precision surface finishes on workpieces. Understanding the different types and technical specifications of surface grinding machine parts is vital for businesses looking to optimize their grinding processes.

Types of Surface Grinding Machine Parts

Surface grinding machine parts encompass a variety of components, each serving a specific function in the grinding process. Some of the key parts include the surface grinding wheel, wheel dressers, spindles, tables, and magnetic chucks. The surface grinding wheel is a critical part that comes in different types such as straight wheels, cylinder wheels, and more, each suitable for specific grinding tasks. Wheel dressers are used to maintain the shape of the grinding wheel for consistent results.

Technical Specifications of Surface Grinding Machine Parts

When selecting surface grinding machine parts, it is essential to consider technical specifications to ensure compatibility and optimal performance. The specifications may include the material of the parts, dimensions, tolerances, hardness, and surface finish requirements. For instance, the surface grinding wheel's specifications may indicate the abrasive material, grit size, bond type, and wheel structure, all of which impact the grinding process's outcome.

Features and Advantages of Surface Grinding Machine Parts

The features of surface grinding machine parts determine their functionality and performance in grinding operations. High-quality parts are designed for durability, precision, and efficient material removal. Additionally, these parts offer advantages such as improved surface finish, dimensional accuracy, and the ability to work with a variety of materials. Investing in premium surface grinding machine parts can enhance productivity and quality in machining processes.

Choosing the Right Surface Grinding Machine Parts

When choosing surface grinder parts, businesses should consider factors like the machine's specifications, application requirements, and desired output quality. It is crucial to select parts from reputable suppliers known for their quality and reliability. Understanding the compatibility of the parts with the specific surface grinding machine model is essential to ensure seamless integration and optimal performance.

Maintenance of Surface Grinding Machine Parts

Proper maintenance of surface grinding machine parts is key to prolonging their lifespan and ensuring consistent performance. Regular inspection, cleaning, and lubrication of critical components such as spindles, tables, and wheel dressers can prevent premature wear and maintain accuracy. Following the manufacturer's maintenance guidelines and scheduling routine servicing can help avoid costly downtime and repairs.

As businesses rely on surface grinding machines for precise surface finishing and material removal, investing in high-quality cylinder head surface grinder parts is essential for achieving optimal results. By understanding the types, technical specifications, features, and maintenance requirements of surface grinding machine parts, businesses can make informed decisions to enhance their grinding processes and overall productivity.